2 月 . 17, 2025 10:41

Back to list

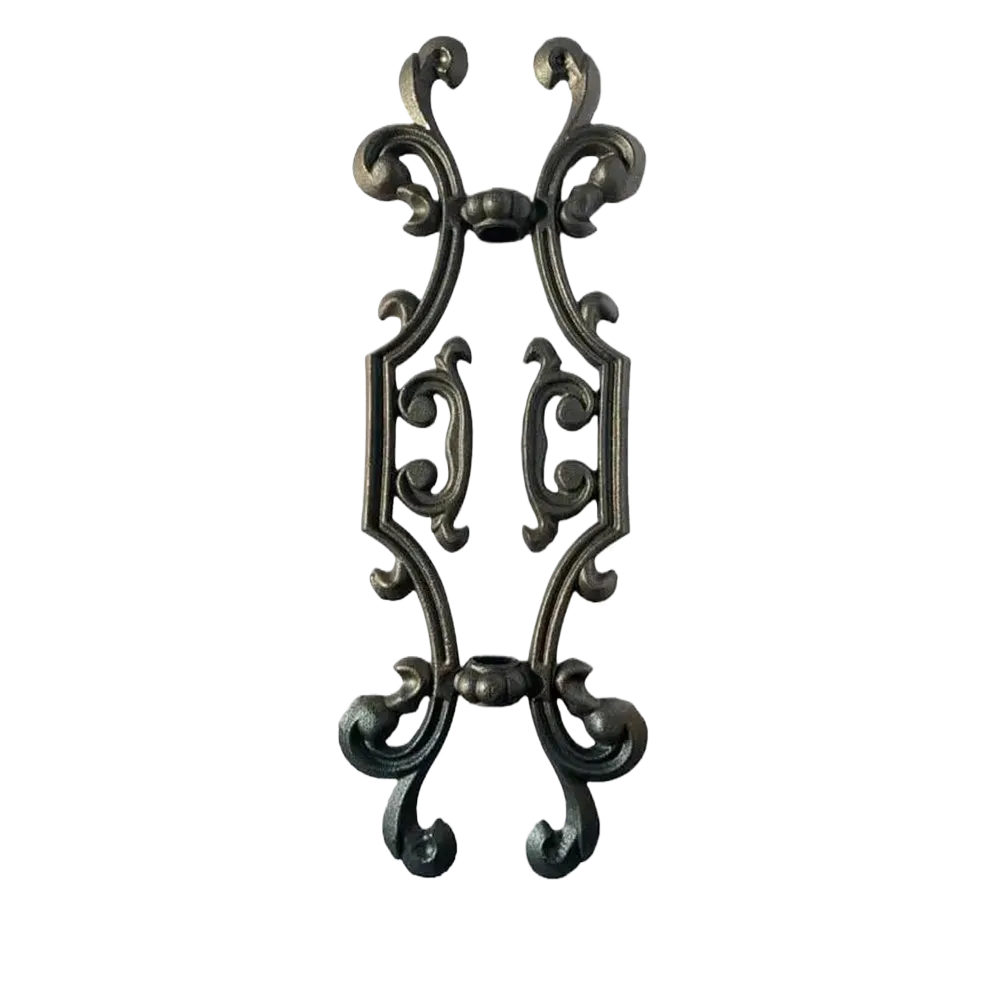

wrought iron railing panels

Wrought iron, a material renowned for its durability and classic appeal, is often used for fences, railings, and a range of decorative items. A common question among those considering wrought iron products is, Can wrought iron rust? The simple answer is yes, however, the more detailed answer reveals why it remains a popular choice and how it can be protected to ensure a long-lasting life.

Routine maintenance is essential to maintaining wrought iron's integrity. Regularly inspecting the metal for signs of rust – such as discoloration or flaky texture – allows for early intervention. If rust is detected, it can be removed using a wire brush or sandpaper, prepared with an appropriate primer, and repainted. For significant corrosion, sandblasting may be required to effectively restore the surface. Location and environmental factors also play a crucial role in the longevity of wrought iron products. Coastal areas, where air contains high levels of salt, may accelerate the rusting process. In these settings, additional preventative measures, like more frequent repainting or using sealants, can offer added protection. Urban areas, affected by pollution, may also hasten rusting, underscoring the importance of regular maintenance. For those seeking an expert manufacturer or supplier, choosing a company with a proven track record in producing high-quality wrought iron products is crucial. Such entities often employ advanced techniques and protective finishes to enhance the metal’s resilience against rust. Moreover, following best practices recommended by these professionals can considerably extend the life of the product. In conclusion, while wrought iron can indeed rust, its propensity to do so can be effectively managed through protective coatings, routine maintenance, and considering environmental factors. This material's aesthetic appeal and structural integrity make it an enduring choice for items needing reliability and charm. Selecting quality wrought iron paired with diligent care can ensure a product that not only meets but exceeds lifespan expectations, providing beauty and strength through generations.

Routine maintenance is essential to maintaining wrought iron's integrity. Regularly inspecting the metal for signs of rust – such as discoloration or flaky texture – allows for early intervention. If rust is detected, it can be removed using a wire brush or sandpaper, prepared with an appropriate primer, and repainted. For significant corrosion, sandblasting may be required to effectively restore the surface. Location and environmental factors also play a crucial role in the longevity of wrought iron products. Coastal areas, where air contains high levels of salt, may accelerate the rusting process. In these settings, additional preventative measures, like more frequent repainting or using sealants, can offer added protection. Urban areas, affected by pollution, may also hasten rusting, underscoring the importance of regular maintenance. For those seeking an expert manufacturer or supplier, choosing a company with a proven track record in producing high-quality wrought iron products is crucial. Such entities often employ advanced techniques and protective finishes to enhance the metal’s resilience against rust. Moreover, following best practices recommended by these professionals can considerably extend the life of the product. In conclusion, while wrought iron can indeed rust, its propensity to do so can be effectively managed through protective coatings, routine maintenance, and considering environmental factors. This material's aesthetic appeal and structural integrity make it an enduring choice for items needing reliability and charm. Selecting quality wrought iron paired with diligent care can ensure a product that not only meets but exceeds lifespan expectations, providing beauty and strength through generations.

Next:

Latest news

-

Why Choose TJJ as Your Window and Door Hardware Manufacturer?NewsOct.28,2024

-

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenNewsOct.28,2024

-

Aluminium Windows Profiles: Benefits and FeaturesNewsOct.28,2024

-

Innovations in Cast Iron Panel TechnologyNewsOct.28,2024

-

The Benefits of Customizing Your Wrought Iron Fence PartsNewsOct.28,2024

-

The Immortal Legacy of Cast Iron Spears: From War to Decorative UseNewsOct.21,2024

-

Why Choose TJJ as Your Window and Door Hardware Manufacturer?Oct-28-2024Why Choose TJJ as Your Window and Door Hardware Manufacturer?

Why Choose TJJ as Your Window and Door Hardware Manufacturer?Oct-28-2024Why Choose TJJ as Your Window and Door Hardware Manufacturer? -

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenOct-28-2024The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your Kitchen

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenOct-28-2024The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your Kitchen -

Aluminium Windows Profiles: Benefits and FeaturesOct-28-2024Aluminium Windows Profiles: Benefits and Features

Aluminium Windows Profiles: Benefits and FeaturesOct-28-2024Aluminium Windows Profiles: Benefits and Features