2 月 . 16, 2025 08:29

Back to list

wrought iron railing panels

Exploring the carbon content of wrought iron reveals a compelling journey through material science that has applications throughout modern industry. Known for its distinctive qualities such as malleability and toughness, wrought iron has been used for centuries, yet its uniqueness is accentuated by its low carbon content.

Remarkably, the carbon content also affects wrought iron's recyclability. The ability to reclaim and reuse wrought iron without significant loss of its intrinsic properties speaks volumes about its sustainability. In a world grappling with environmental challenges, wrought iron’s longevity and recyclability position it as an exemplary material in sustainable practice. Local markets and communities benefit from this, as wrought iron structures often become historical landmarks, reducing the need for constant replacement and resource depletion. From a product perspective, wrought iron's carbon content ensures the mitigation of problems associated with high-carbon steels, such as cracking and brittleness under colder temperatures. Architectural projects ongoing in adverse climates favor wrought iron for its resilience and adaptability. Moreover, in such environments, the material's chemical purity—stemming from its minimal carbon content—proves invaluable. Products tailored to these conditions with wrought iron ensure longevity and integrity, potentially reducing the frequency and cost of repairs or replacements. Authoritative sources within metallurgical research consistently affirm the unique benefits provided by wrought iron's specific composition. As such, it shares a pivotal place in industries that demand not only rigorous material characteristics but also environmental conscientiousness. Wrought iron stands substantiated as both a historical asset and a sophisticated modern-day solution, harmonizing artistry with scientific insights. Consumers and industry professionals alike are turning back to wrought iron for solutions that highlight authenticity and long-term performance. Whether for heritage preservation or contemporary innovation, wrought iron remains trusted for projects where excellence, heritage, and sustainability converge. It is indeed the nuanced understanding of its carbon content that empowers skilled craftsmen and designers to push the material’s applications into both revered and new frontiers. As industries seek materials that blend time-honored techniques with cutting-edge knowledge, wrought iron stands as a testament to the benefits wrought by low-carbon ingenuity.

Remarkably, the carbon content also affects wrought iron's recyclability. The ability to reclaim and reuse wrought iron without significant loss of its intrinsic properties speaks volumes about its sustainability. In a world grappling with environmental challenges, wrought iron’s longevity and recyclability position it as an exemplary material in sustainable practice. Local markets and communities benefit from this, as wrought iron structures often become historical landmarks, reducing the need for constant replacement and resource depletion. From a product perspective, wrought iron's carbon content ensures the mitigation of problems associated with high-carbon steels, such as cracking and brittleness under colder temperatures. Architectural projects ongoing in adverse climates favor wrought iron for its resilience and adaptability. Moreover, in such environments, the material's chemical purity—stemming from its minimal carbon content—proves invaluable. Products tailored to these conditions with wrought iron ensure longevity and integrity, potentially reducing the frequency and cost of repairs or replacements. Authoritative sources within metallurgical research consistently affirm the unique benefits provided by wrought iron's specific composition. As such, it shares a pivotal place in industries that demand not only rigorous material characteristics but also environmental conscientiousness. Wrought iron stands substantiated as both a historical asset and a sophisticated modern-day solution, harmonizing artistry with scientific insights. Consumers and industry professionals alike are turning back to wrought iron for solutions that highlight authenticity and long-term performance. Whether for heritage preservation or contemporary innovation, wrought iron remains trusted for projects where excellence, heritage, and sustainability converge. It is indeed the nuanced understanding of its carbon content that empowers skilled craftsmen and designers to push the material’s applications into both revered and new frontiers. As industries seek materials that blend time-honored techniques with cutting-edge knowledge, wrought iron stands as a testament to the benefits wrought by low-carbon ingenuity.

Next:

Latest news

-

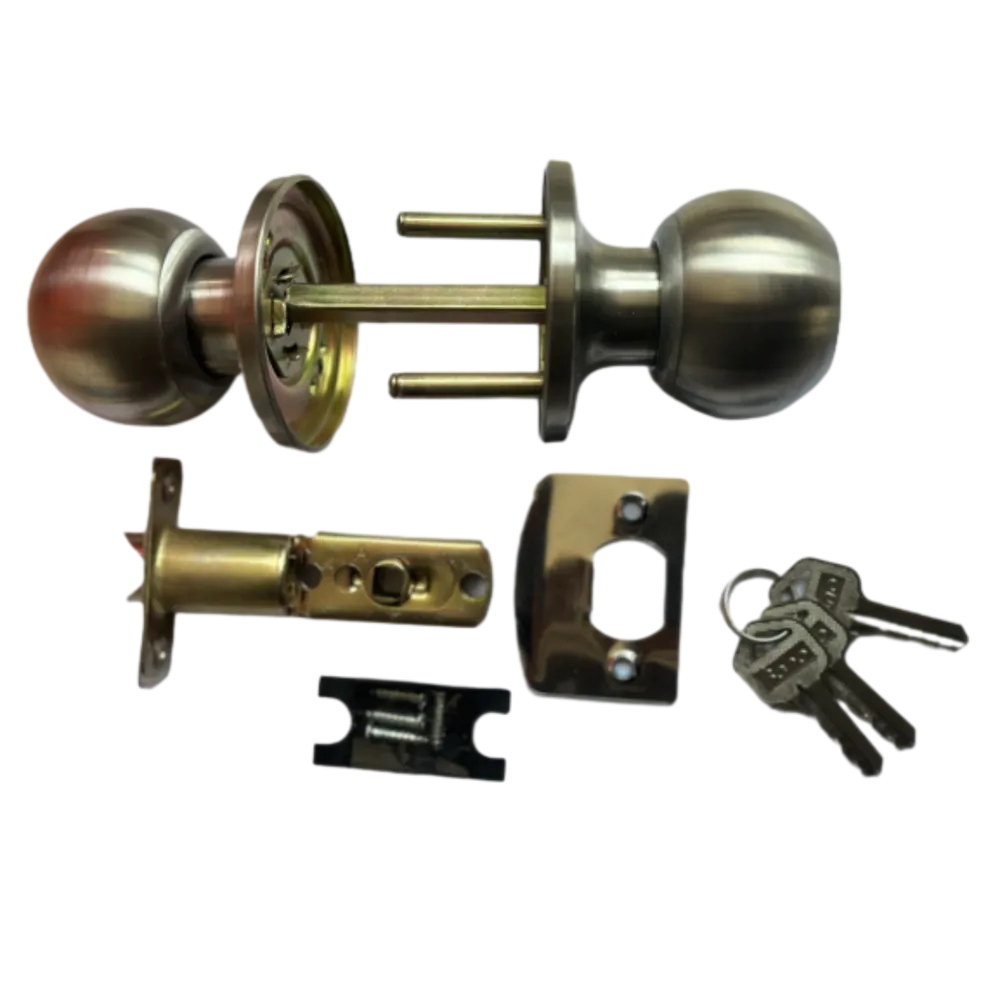

Why Choose TJJ as Your Window and Door Hardware Manufacturer?NewsOct.28,2024

-

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenNewsOct.28,2024

-

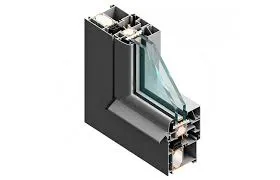

Aluminium Windows Profiles: Benefits and FeaturesNewsOct.28,2024

-

Innovations in Cast Iron Panel TechnologyNewsOct.28,2024

-

The Benefits of Customizing Your Wrought Iron Fence PartsNewsOct.28,2024

-

The Immortal Legacy of Cast Iron Spears: From War to Decorative UseNewsOct.21,2024

-

Why Choose TJJ as Your Window and Door Hardware Manufacturer?Oct-28-2024Why Choose TJJ as Your Window and Door Hardware Manufacturer?

Why Choose TJJ as Your Window and Door Hardware Manufacturer?Oct-28-2024Why Choose TJJ as Your Window and Door Hardware Manufacturer? -

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenOct-28-2024The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your Kitchen

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenOct-28-2024The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your Kitchen -

Aluminium Windows Profiles: Benefits and FeaturesOct-28-2024Aluminium Windows Profiles: Benefits and Features

Aluminium Windows Profiles: Benefits and FeaturesOct-28-2024Aluminium Windows Profiles: Benefits and Features