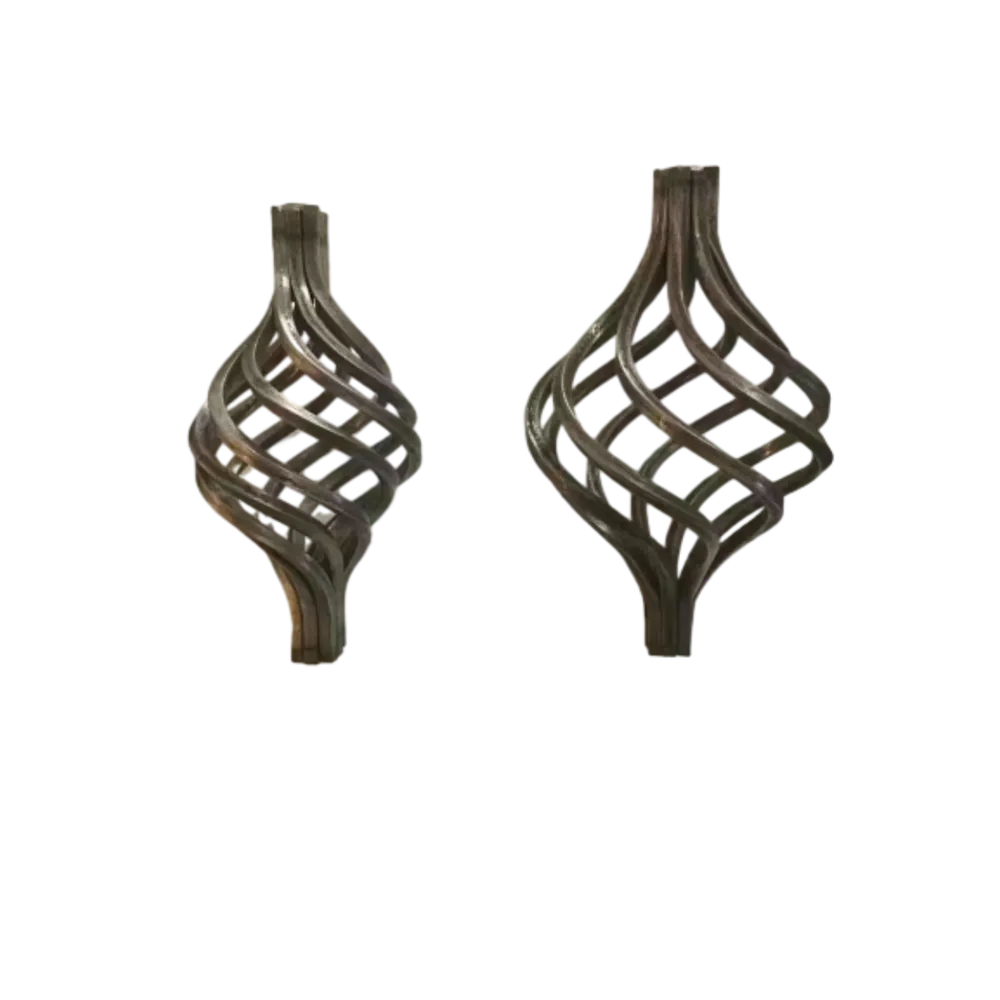

cast iron ball point

The Evolution and Applications of Cast Iron Ball Points

Cast iron has been a crucial material in various industries for centuries, prized for its durability and versatility. One fascinating application of cast iron is in the manufacturing of ball points, particularly for pens and other writing instruments. The unique properties of cast iron make it an ideal candidate for this purpose, leading to a blend of artistry and functionality that is remarkable in its own right.

Historically, cast iron has been utilized since the Han Dynasty in China (206 BC - 220 AD) for various purposes, ranging from cookware to complex machinery. Its ability to withstand high temperatures and pressure enables it to be molded into intricate shapes, making it a favorite among artisans and engineers alike. The advent of the modern pen during the 19th century ushered in a need for materials that could provide a smooth writing experience while being durable enough to withstand regular use. Cast iron emerged as a promising option.

Casting, a process that involves pouring molten metal into a mold where it solidifies into a specific shape, is incredibly effective for producing ball points. The ball point is typically the tip of a pen or marker that transfers ink onto paper in a controlled manner. When produced from cast iron, the ball point benefits from the material's strength, which ensures a consistent and reliable writing experience. Moreover, the weighty nature of cast iron adds a level of stability to the pen, allowing for a smoother flow and reduced hand fatigue during prolonged use.

Designers and manufacturers have embraced the aesthetic qualities of cast iron as well. The finish of cast iron can be both rustic and elegant, providing a unique look that appeals to consumers seeking not just functionality but also style in their writing instruments. Ballpoint pens featuring cast iron tips often exhibit a handcrafted essence, merging traditional techniques with modern demands. In a world dominated by mass production, a cast iron ball point represents a return to quality, craftsmanship, and individuality.

cast iron ball point

Beyond writing instruments, the principles harnessed through the production of cast iron ball points have found their way into other sectors. For instance, manufacturing processes inspired by pen design have been employed in creating intricate machine parts that require precision and durability. This cross-industry influence showcases the adaptability of cast iron and suggests that even the simplest of objects can have far-reaching implications in engineering and design.

The environmental aspect of using cast iron is also relevant today. With the rise of sustainability movements, the demand for recyclable materials has increased significantly. Cast iron has an impressive recycling rate, and its longevity means that products manufactured from it are less likely to end up in landfills. Therefore, opting for cast iron ball points can be viewed as a choice that aligns with eco-friendly practices, supporting the notion that consumers can influence production methods and material choices through their buying decisions.

Looking forward, the future of cast iron ball points appears promising. As technology continues to evolve, innovations in the way materials are processed and combined may lead to even more refined versions of these writing instruments. Enhanced manufacturing techniques can improve the consistency of cast iron components and lead to even more intricate designs. There's also potential for collaborative efforts between artisans and engineers to create bespoke items that cater to niche markets, further solidifying cast iron’s place in the modern landscape.

In conclusion, the journey of cast iron ball points from an ancient material to a beloved feature in contemporary writing instruments underscores the importance of history, functionality, and aesthetic value in product design. As we continue to explore the intersections of tradition and innovation, cast iron remains a testament to the enduring nature of good craftsmanship.

-

Why Choose TJJ as Your Window and Door Hardware Manufacturer?NewsOct.28,2024

-

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenNewsOct.28,2024

-

Aluminium Windows Profiles: Benefits and FeaturesNewsOct.28,2024

-

Innovations in Cast Iron Panel TechnologyNewsOct.28,2024

-

The Benefits of Customizing Your Wrought Iron Fence PartsNewsOct.28,2024

-

The Immortal Legacy of Cast Iron Spears: From War to Decorative UseNewsOct.21,2024

-

Why Choose TJJ as Your Window and Door Hardware Manufacturer?Oct-28-2024Why Choose TJJ as Your Window and Door Hardware Manufacturer?

Why Choose TJJ as Your Window and Door Hardware Manufacturer?Oct-28-2024Why Choose TJJ as Your Window and Door Hardware Manufacturer? -

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenOct-28-2024The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your Kitchen

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenOct-28-2024The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your Kitchen -

Aluminium Windows Profiles: Benefits and FeaturesOct-28-2024Aluminium Windows Profiles: Benefits and Features

Aluminium Windows Profiles: Benefits and FeaturesOct-28-2024Aluminium Windows Profiles: Benefits and Features