2 月 . 18, 2025 11:16

Back to list

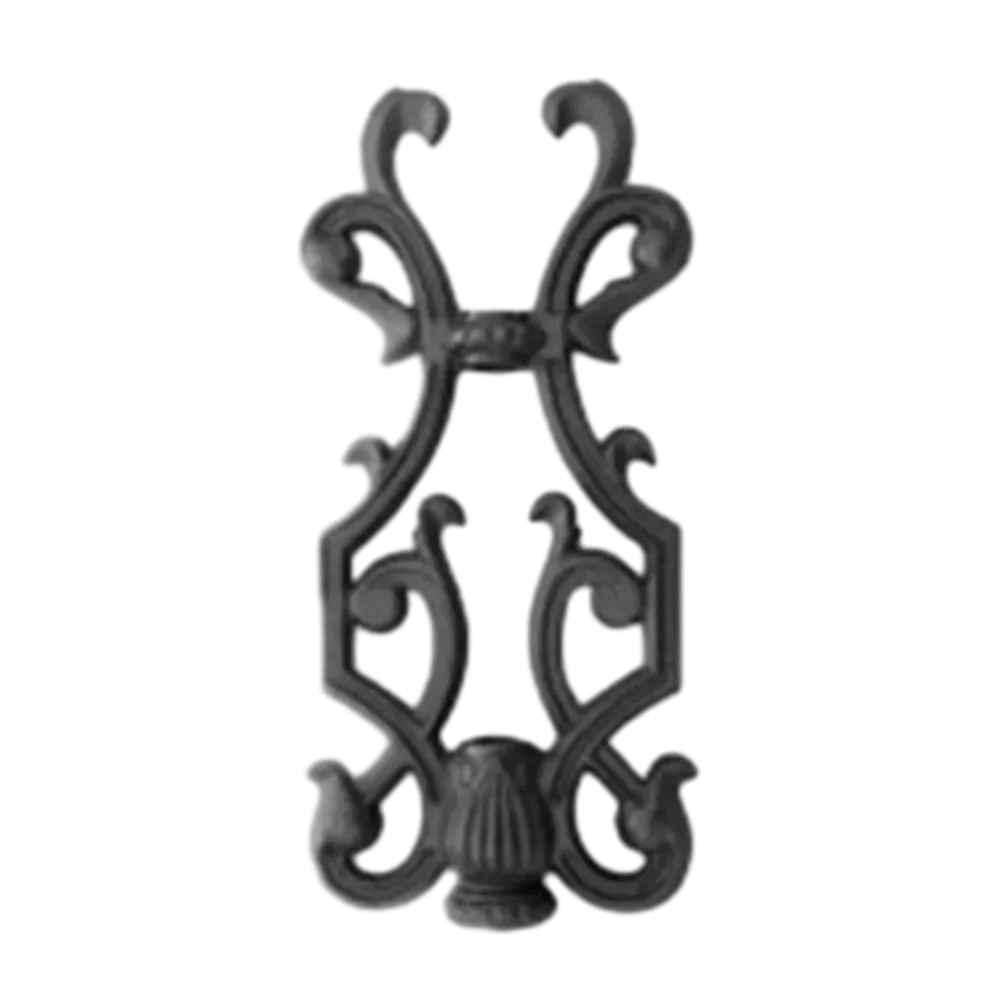

Cast Iron Panel

Cast iron balls, also known as grinding balls, play a crucial role in the milling and pulverizing industries, widely used in mining, cement, and chemical processing sectors. These industrial staples are indispensable for crushing, grinding, and dispersing materials, which makes their quality and reliability a focal point of industry experts.

Authoritativeness in Industry Several authoritative bodies and industry experts have reinforced the importance of quality assurance when it comes to these grinding aids. The American Society for Testing and Materials (ASTM) sets stringent standards for the mechanical properties and chemical composition of cast iron that serve as a guideline for manufacturers across the globe. Adherence to these standards is not only a mark of quality but also a necessity to achieve the efficiency and reliability demanded by industrial applications. Leading companies in the mining and chemical processing industries depend on these standards to ensure their operational success and longevity of their equipment. Trustworthiness and Reliability Trust in the product is built through consistent performance, and cast iron balls hold a reputation that stands the test of time. Regular assessments and improvements on manufacturing techniques have led these balls to achieve higher precision and uniformity, which translates directly to performance reliability. When dealing with exceptionally high-volume demand, businesses look for solutions that minimize downtime, and the inherent dependability of cast iron balls meets this need effectively. Feedback from plant managers and process engineers often highlights the cost-effectiveness of using cast iron balls, as their robust nature significantly reduces frequency of replacement compared to other materials. In conclusion, cast iron balls are a pivotal component in sectors that require efficient and reliable grinding solutions. Their comprehensive benefits range from mechanical performance to economic viability. Standing as an enduring testament to material engineering prowess, cast iron balls represent the perfect amalgamation of past industry insights and modern manufacturing technology. This synergy is what propels their continued preference and trust amongst users worldwide, making cast iron balls an indispensable element in heavy industries.

Authoritativeness in Industry Several authoritative bodies and industry experts have reinforced the importance of quality assurance when it comes to these grinding aids. The American Society for Testing and Materials (ASTM) sets stringent standards for the mechanical properties and chemical composition of cast iron that serve as a guideline for manufacturers across the globe. Adherence to these standards is not only a mark of quality but also a necessity to achieve the efficiency and reliability demanded by industrial applications. Leading companies in the mining and chemical processing industries depend on these standards to ensure their operational success and longevity of their equipment. Trustworthiness and Reliability Trust in the product is built through consistent performance, and cast iron balls hold a reputation that stands the test of time. Regular assessments and improvements on manufacturing techniques have led these balls to achieve higher precision and uniformity, which translates directly to performance reliability. When dealing with exceptionally high-volume demand, businesses look for solutions that minimize downtime, and the inherent dependability of cast iron balls meets this need effectively. Feedback from plant managers and process engineers often highlights the cost-effectiveness of using cast iron balls, as their robust nature significantly reduces frequency of replacement compared to other materials. In conclusion, cast iron balls are a pivotal component in sectors that require efficient and reliable grinding solutions. Their comprehensive benefits range from mechanical performance to economic viability. Standing as an enduring testament to material engineering prowess, cast iron balls represent the perfect amalgamation of past industry insights and modern manufacturing technology. This synergy is what propels their continued preference and trust amongst users worldwide, making cast iron balls an indispensable element in heavy industries.

Next:

Latest news

-

Why Choose TJJ as Your Window and Door Hardware Manufacturer?NewsOct.28,2024

-

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenNewsOct.28,2024

-

Aluminium Windows Profiles: Benefits and FeaturesNewsOct.28,2024

-

Innovations in Cast Iron Panel TechnologyNewsOct.28,2024

-

The Benefits of Customizing Your Wrought Iron Fence PartsNewsOct.28,2024

-

The Immortal Legacy of Cast Iron Spears: From War to Decorative UseNewsOct.21,2024

-

Why Choose TJJ as Your Window and Door Hardware Manufacturer?Oct-28-2024Why Choose TJJ as Your Window and Door Hardware Manufacturer?

Why Choose TJJ as Your Window and Door Hardware Manufacturer?Oct-28-2024Why Choose TJJ as Your Window and Door Hardware Manufacturer? -

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenOct-28-2024The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your Kitchen

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenOct-28-2024The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your Kitchen -

Aluminium Windows Profiles: Benefits and FeaturesOct-28-2024Aluminium Windows Profiles: Benefits and Features

Aluminium Windows Profiles: Benefits and FeaturesOct-28-2024Aluminium Windows Profiles: Benefits and Features