2 月 . 14, 2025 17:18

Back to list

cast iron collar and bushings

Cast iron bushings are a cornerstone component in a myriad of industrial applications, prized for their durability, robustness, and performance in high-stress environments. With decades of engineering evolution imbued within them, these metallic cylinders serve as pivotal elements in the machinery that powers our modern world.

Trustworthiness in cast iron bushings is often reflected through rigorous testing methods. Non-destructive testing (NDT) techniques, such as ultrasonic or magnetic particle testing, are employed to detect any imperfections that might compromise structural integrity. This commitment to quality assurance fortifies confidence in these components, ensuring they function reliably under demanding conditions. In the competitive landscape of industrial manufacturing, the differentiating factor for a cast iron bushing often lies in the subtle nuances of craftsmanship. Skilled machinists, utilizing CNC machining and precise grinding techniques, enhance the bushing’s surface finish and dimensional accuracy, tailoring them to fit bespoke client specifications. Connoisseurs of machinery understand that choosing a supplier with a track record of expertise in metallurgy and precision engineering is indispensable. A supplier’s authoritative stance in the market is built on years of research, innovation, and a deep understanding of customer needs, which translates into products that not only meet but exceed expectations in performance and lifespan. For industries such as automotive, aerospace, and manufacturing, where reliability is non-negotiable, investing in high-quality cast iron bushings is a testament to their trust in proven engineering principles and materials science. Steering clear of substandard substitutes is essential, as the long-term cost implications and potential operational setbacks from inferior components far outweigh the initial investment in premium quality bushings. As industries advance, the role of cast iron bushings will continue to evolve, with ongoing research and development pushing the boundaries of what these components can achieve. Emerging technologies such as additive manufacturing and advanced material science hold promise for future innovations in bushing design and application, ensuring that cast iron bushings remain an integral part of industrial machinery for generations to come.

Trustworthiness in cast iron bushings is often reflected through rigorous testing methods. Non-destructive testing (NDT) techniques, such as ultrasonic or magnetic particle testing, are employed to detect any imperfections that might compromise structural integrity. This commitment to quality assurance fortifies confidence in these components, ensuring they function reliably under demanding conditions. In the competitive landscape of industrial manufacturing, the differentiating factor for a cast iron bushing often lies in the subtle nuances of craftsmanship. Skilled machinists, utilizing CNC machining and precise grinding techniques, enhance the bushing’s surface finish and dimensional accuracy, tailoring them to fit bespoke client specifications. Connoisseurs of machinery understand that choosing a supplier with a track record of expertise in metallurgy and precision engineering is indispensable. A supplier’s authoritative stance in the market is built on years of research, innovation, and a deep understanding of customer needs, which translates into products that not only meet but exceed expectations in performance and lifespan. For industries such as automotive, aerospace, and manufacturing, where reliability is non-negotiable, investing in high-quality cast iron bushings is a testament to their trust in proven engineering principles and materials science. Steering clear of substandard substitutes is essential, as the long-term cost implications and potential operational setbacks from inferior components far outweigh the initial investment in premium quality bushings. As industries advance, the role of cast iron bushings will continue to evolve, with ongoing research and development pushing the boundaries of what these components can achieve. Emerging technologies such as additive manufacturing and advanced material science hold promise for future innovations in bushing design and application, ensuring that cast iron bushings remain an integral part of industrial machinery for generations to come.

Next:

Latest news

-

Why Choose TJJ as Your Window and Door Hardware Manufacturer?NewsOct.28,2024

-

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenNewsOct.28,2024

-

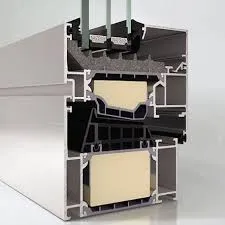

Aluminium Windows Profiles: Benefits and FeaturesNewsOct.28,2024

-

Innovations in Cast Iron Panel TechnologyNewsOct.28,2024

-

The Benefits of Customizing Your Wrought Iron Fence PartsNewsOct.28,2024

-

The Immortal Legacy of Cast Iron Spears: From War to Decorative UseNewsOct.21,2024

-

Why Choose TJJ as Your Window and Door Hardware Manufacturer?Oct-28-2024Why Choose TJJ as Your Window and Door Hardware Manufacturer?

Why Choose TJJ as Your Window and Door Hardware Manufacturer?Oct-28-2024Why Choose TJJ as Your Window and Door Hardware Manufacturer? -

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenOct-28-2024The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your Kitchen

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenOct-28-2024The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your Kitchen -

Aluminium Windows Profiles: Benefits and FeaturesOct-28-2024Aluminium Windows Profiles: Benefits and Features

Aluminium Windows Profiles: Benefits and FeaturesOct-28-2024Aluminium Windows Profiles: Benefits and Features