Exploring the Benefits and Applications of Cast Iron Components in Modern Engineering

The Versatility and Importance of Cast Iron Components

Cast iron has long been favored in various industries for its unique properties, which make it an ideal material for a wide range of components. From automotive parts to cookware, cast iron components play a vital role in everyday life and industrial applications. This article explores the significance, manufacturing processes, and applications of cast iron components, highlighting their versatility and benefits.

What is Cast Iron?

Cast iron is an iron-carbon alloy with a carbon content greater than 2%. It is characterized by its excellent castability, wear resistance, and durability. The primary types of cast iron include gray iron, ductile iron, white iron, and malleable iron, each having distinct properties and applications. Gray iron contains flake-shaped graphite, while ductile iron has a spherical graphite structure, giving it enhanced strength and ductility. These characteristics make cast iron components suitable for various engineering applications.

Manufacturing Process

The manufacturing of cast iron components involves several key stages melting, pouring, solidification, and finishing. The process typically begins with melting raw materials, including iron scrap, pig iron, and alloying elements, in a furnace. Once the molten iron reaches the desired temperature, it is poured into molds. These molds can be made from sand, metal, or ceramic, depending on the required precision and finish of the component.

After pouring, the molten iron fills the mold cavity and begins to solidify. The cooling rate during solidification affects the microstructure and properties of the final product. Once cooled, the cast iron component is removed from the mold and subjected to various finishing processes, such as machining, grinding, or surface treatment, to achieve the desired specifications. This process allows for the production of complex shapes and designs that would be difficult to achieve with other materials.

Advantages of Cast Iron Components

1. Durability and Strength One of the most notable advantages of cast iron components is their exceptional durability and strength. They can withstand high levels of stress and wear, making them ideal for use in heavy machinery and construction equipment.

2. Castability Cast iron can be easily cast into intricate shapes, enabling manufacturers to create complex components without the need for extensive machining. This reduces material waste and production costs.

3. Wear Resistance Due to its hard structure and graphite content, cast iron exhibits impressive wear resistance, making it suitable for applications that involve friction and high temperatures.

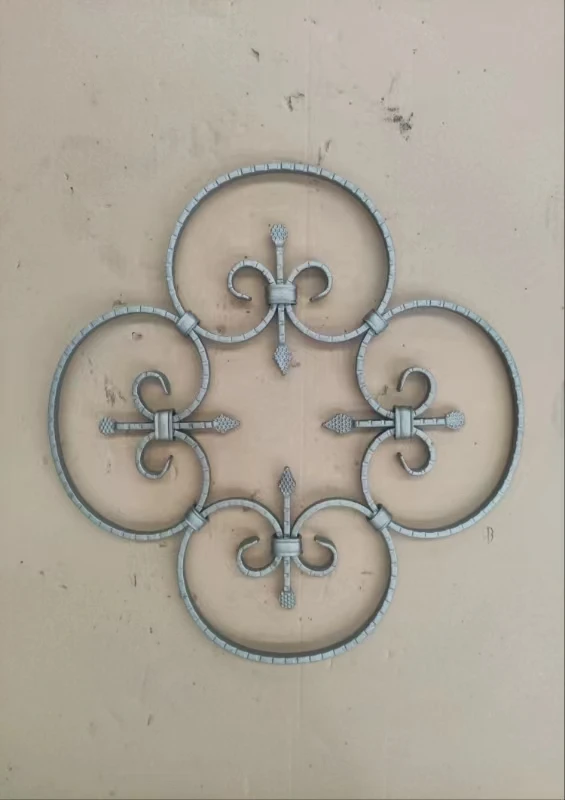

cast iron component

4. Thermal Conductivity Cast iron has excellent thermal conductivity, making it perfect for cooking utensils, such as frying pans and Dutch ovens. It distributes heat evenly, ensuring consistent cooking results.

5. Cost-effectiveness Compared to some alternatives, cast iron is relatively inexpensive and readily available, making it an economical choice for manufacturers and consumers alike.

Applications of Cast Iron Components

Cast iron components are used across various industries, reflecting their extensive application range. Some prominent examples include

- Automotive Industry Cast iron is commonly used for engine blocks, cylinder heads, and brake discs due to its strength and heat resistance.

- Construction and Infrastructure Pipes, manhole covers, and structural supports in buildings often utilize cast iron for its durability and load-bearing capabilities.

- Machinery and Equipment Many industrial machines, such as lathes and milling machines, rely on cast iron components for stability and vibration dampening.

- Cookware The culinary world widely embraces cast iron for its excellent heat retention and ability to achieve high cooking temperatures.

Conclusion

In summary, cast iron components are an integral part of modern manufacturing and everyday life. Their unique properties, combined with efficient manufacturing processes, make them a preferred choice in various applications across different industries. As technology continues to evolve, the versatility of cast iron ensures that it will remain a vital material, serving both functional and aesthetic purposes. Whether in the form of automotive parts or beloved cookware, cast iron components continue to demonstrate their value time and again.

-

Why Choose TJJ as Your Window and Door Hardware Manufacturer?NewsOct.28,2024

-

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenNewsOct.28,2024

-

Aluminium Windows Profiles: Benefits and FeaturesNewsOct.28,2024

-

Innovations in Cast Iron Panel TechnologyNewsOct.28,2024

-

The Benefits of Customizing Your Wrought Iron Fence PartsNewsOct.28,2024

-

The Immortal Legacy of Cast Iron Spears: From War to Decorative UseNewsOct.21,2024

-

Why Choose TJJ as Your Window and Door Hardware Manufacturer?Oct-28-2024Why Choose TJJ as Your Window and Door Hardware Manufacturer?

Why Choose TJJ as Your Window and Door Hardware Manufacturer?Oct-28-2024Why Choose TJJ as Your Window and Door Hardware Manufacturer? -

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenOct-28-2024The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your Kitchen

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenOct-28-2024The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your Kitchen -

Aluminium Windows Profiles: Benefits and FeaturesOct-28-2024Aluminium Windows Profiles: Benefits and Features

Aluminium Windows Profiles: Benefits and FeaturesOct-28-2024Aluminium Windows Profiles: Benefits and Features