3 月 . 05, 2025 01:54

Back to list

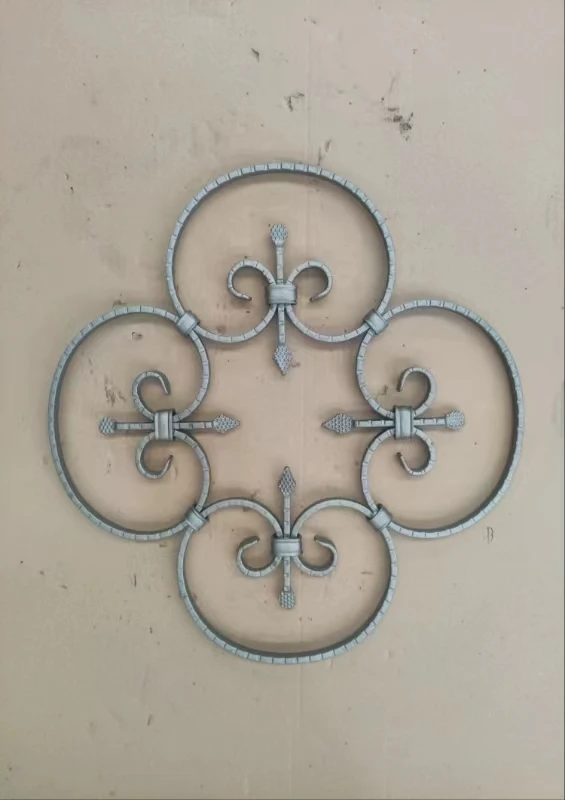

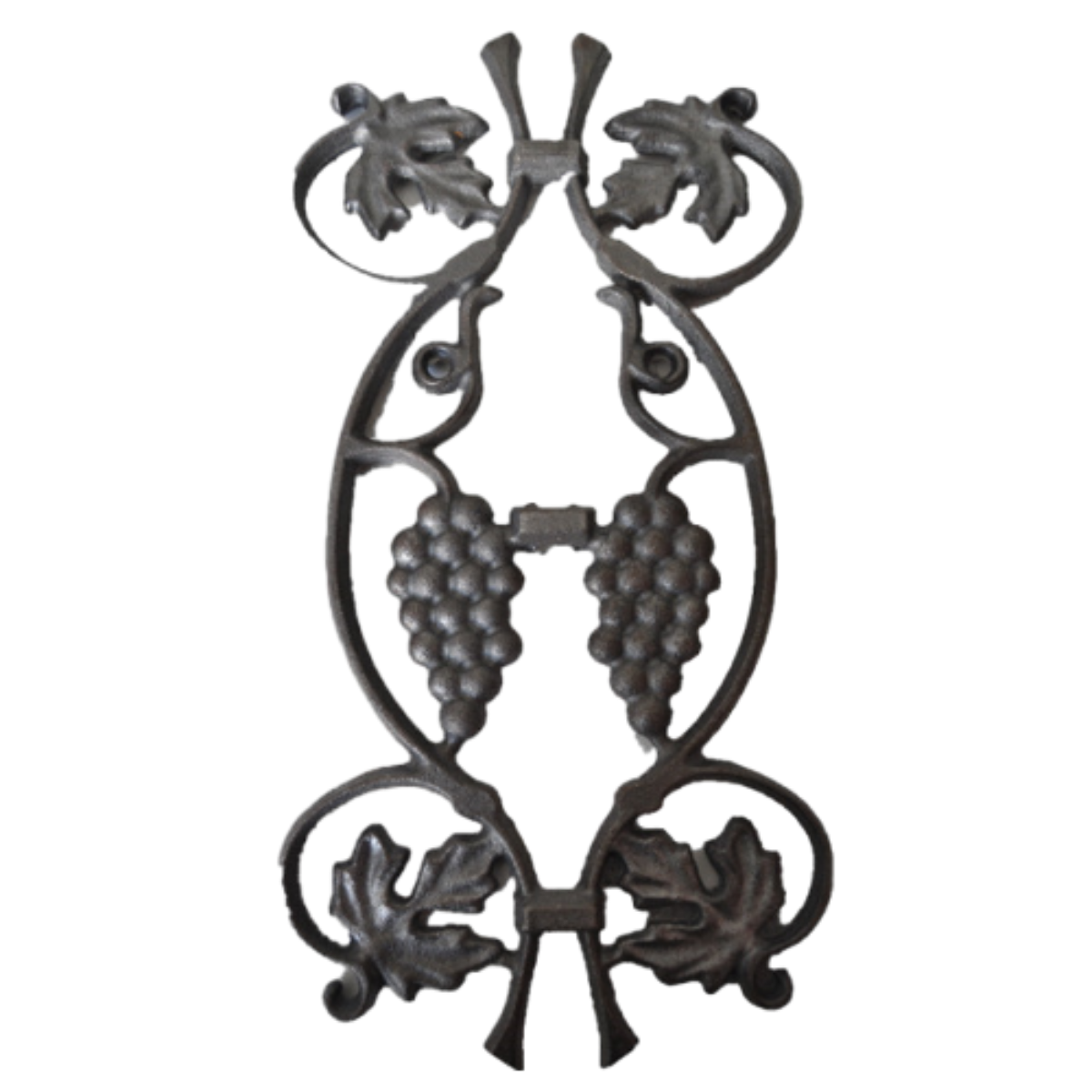

cast iron parts

Cast iron parts have long held an esteemed position in various industries due to their exceptional durability, thermal conductivity, and machinability. Widely utilized in sectors ranging from automotive to architecture, these components cater to a diverse range of applications. A deep dive into the intricacies of cast iron parts reveals a product that melds technical proficiency with historical value, reflecting centuries of evolution and innovation.

In the realm of cookware, cast iron parts are synonymous with culinary performance. Seasoned cast iron skillets, with their naturally non-stick surfaces, are a staple in both home kitchens and professional culinary settings. Their ability to retain and evenly distribute heat makes them ideal for searing, sautéing, and slow-cooking. These attributes are not solely confined to cookware but echo in industrial applications where consistent thermal properties are necessary, such as in furnace parts and heat exchangers. Trustworthiness in cast iron parts is underlined by their reliability over decades of service. Industries dependent on these components can attest to their consistent performance under varied conditions. This reliability is ensured through rigorous testing and quality control measures at every step of the manufacturing process, from initial material selection to final finishing. Standards such as ASTM and ISO provide frameworks that manufacturers adhere to, ensuring that every cast iron part delivered meets specified performance criteria and safety standards. Authoritativeness in the field of cast iron parts is bolstered by continuous research and advancements in materials science. Innovations, such as advanced alloying techniques and precision casting methods, have expanded the capabilities of cast iron parts, allowing them to meet the demanding specifications of modern engineering. With a lineage tracing back to ancient China and medieval Europe, modern industry leaders continue to build upon this rich heritage, pushing boundaries and setting new standards of excellence. In summary, cast iron parts stand as a testament to engineering expertise and historical legacy. Their enduring presence across various industries highlights not only their adaptability and performance but also the confidence they inspire among professionals who rely on them. Companies looking to ensure longevity and reliability in their core infrastructures or products would be well-advised to explore the manifold benefits that cast iron parts have to offer. As technology advances, cast iron remains an essential component, merging traditional craftsmanship with cutting-edge innovation.

In the realm of cookware, cast iron parts are synonymous with culinary performance. Seasoned cast iron skillets, with their naturally non-stick surfaces, are a staple in both home kitchens and professional culinary settings. Their ability to retain and evenly distribute heat makes them ideal for searing, sautéing, and slow-cooking. These attributes are not solely confined to cookware but echo in industrial applications where consistent thermal properties are necessary, such as in furnace parts and heat exchangers. Trustworthiness in cast iron parts is underlined by their reliability over decades of service. Industries dependent on these components can attest to their consistent performance under varied conditions. This reliability is ensured through rigorous testing and quality control measures at every step of the manufacturing process, from initial material selection to final finishing. Standards such as ASTM and ISO provide frameworks that manufacturers adhere to, ensuring that every cast iron part delivered meets specified performance criteria and safety standards. Authoritativeness in the field of cast iron parts is bolstered by continuous research and advancements in materials science. Innovations, such as advanced alloying techniques and precision casting methods, have expanded the capabilities of cast iron parts, allowing them to meet the demanding specifications of modern engineering. With a lineage tracing back to ancient China and medieval Europe, modern industry leaders continue to build upon this rich heritage, pushing boundaries and setting new standards of excellence. In summary, cast iron parts stand as a testament to engineering expertise and historical legacy. Their enduring presence across various industries highlights not only their adaptability and performance but also the confidence they inspire among professionals who rely on them. Companies looking to ensure longevity and reliability in their core infrastructures or products would be well-advised to explore the manifold benefits that cast iron parts have to offer. As technology advances, cast iron remains an essential component, merging traditional craftsmanship with cutting-edge innovation.

Latest news

-

Why Choose TJJ as Your Window and Door Hardware Manufacturer?NewsOct.28,2024

-

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenNewsOct.28,2024

-

Aluminium Windows Profiles: Benefits and FeaturesNewsOct.28,2024

-

Innovations in Cast Iron Panel TechnologyNewsOct.28,2024

-

The Benefits of Customizing Your Wrought Iron Fence PartsNewsOct.28,2024

-

The Immortal Legacy of Cast Iron Spears: From War to Decorative UseNewsOct.21,2024

-

Why Choose TJJ as Your Window and Door Hardware Manufacturer?Oct-28-2024Why Choose TJJ as Your Window and Door Hardware Manufacturer?

Why Choose TJJ as Your Window and Door Hardware Manufacturer?Oct-28-2024Why Choose TJJ as Your Window and Door Hardware Manufacturer? -

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenOct-28-2024The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your Kitchen

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenOct-28-2024The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your Kitchen -

Aluminium Windows Profiles: Benefits and FeaturesOct-28-2024Aluminium Windows Profiles: Benefits and Features

Aluminium Windows Profiles: Benefits and FeaturesOct-28-2024Aluminium Windows Profiles: Benefits and Features