3 月 . 04, 2025 11:20

Back to list

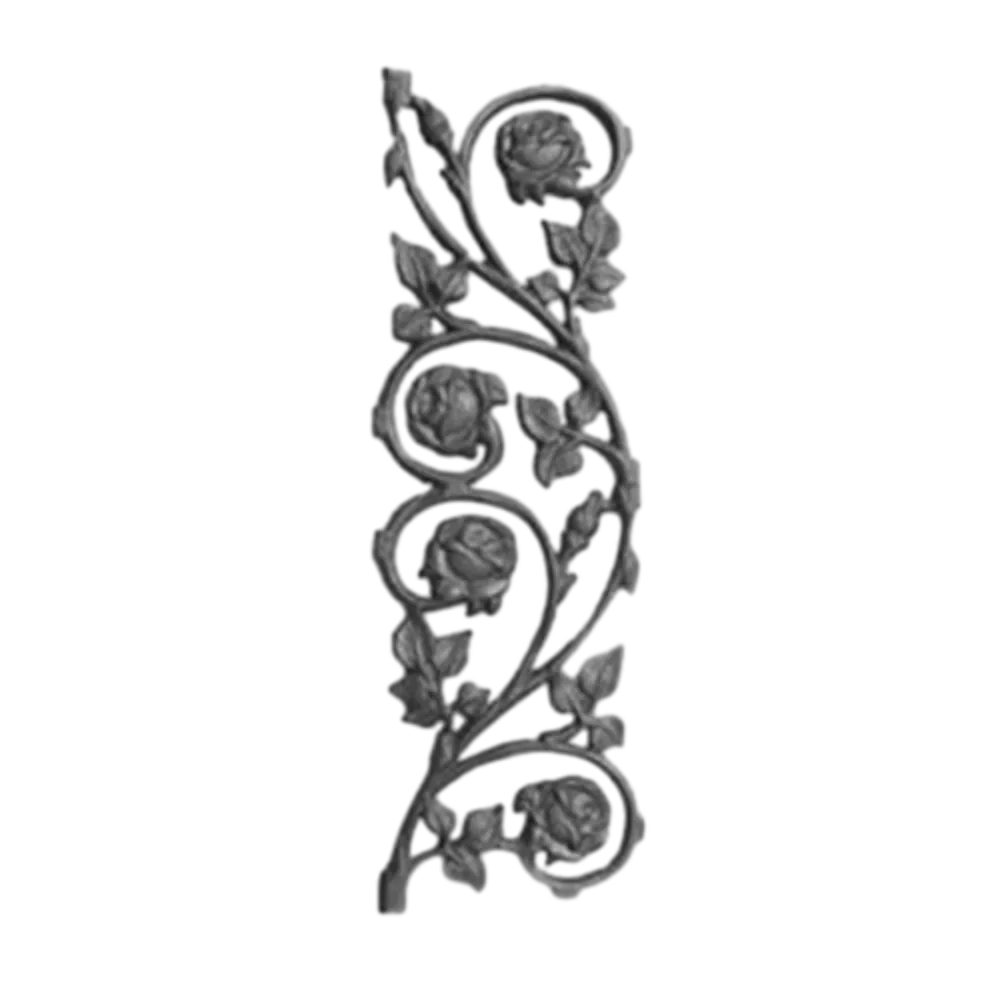

Cast Iron Panel

Cast iron pipe fittings have long been heralded for their durability and resilience in both residential and industrial applications, offering a timeless solution to plumbing challenges. Their robust nature makes them a preferred choice among professionals who seek reliability in high-pressure systems and environments exposed to corrosive elements. Through a deeper exploration of these traits, one can better understand why cast iron pipe fittings remain integral to modern infrastructure.

Across industries, the installation ease and versatility of cast iron pipe fittings further enhance their appeal. With standardized sizing and a comprehensive range of connectors, elbows, and reducers, these fittings can be seamlessly integrated into existing systems. Professional installers appreciate the predictability and uniformity of cast iron fittings, which facilitate a smoother installation process and reduce downtime in retrofitting scenarios. In addition, the element of fire resistance offers significant value to cast iron pipe systems, especially in buildings. Unlike plastic counterparts that can melt or emit toxic gases when exposed to high temperatures, cast iron maintains its form, providing an additional safety layer in the event of a fire. This characteristic not only helps in protecting structural integrity but also aids in complying with stringent building codes and safety regulations. Quality assurance and standard compliance are pivotal in the manufacture of cast iron pipe fittings. Leading manufacturers adopt rigorous testing protocols to ensure each fitting not only meets but often exceeds industry standards. These include tests for tensile strength, dimensional accuracy, and hydrostatic pressure resistance. Such diligence in manufacturing not only elevates the performance of the fittings but also instills confidence in consumers and stakeholders relying on these components for critical infrastructure. Moreover, the lifecycle cost benefits of using cast iron pipe fittings cannot be overstated. While the upfront cost may be higher compared to alternatives like PVC or steel, the long-term savings define their true value. Reduced maintenance, lower probability of failure, and minimal replacement needs contribute to a more economical solution over the lifespan of the piping system. In conclusion, cast iron pipe fittings stand as a testament to superior engineering and material science. Their robustness, noise-reduction capabilities, adaptability, and sustainable production methods set them apart in a crowded marketplace. Professionals across the globe continue to specify cast iron pipe fittings for new builds and renovation projects alike, attributed to their proven track record and unmatched performance. For those seeking reliability and excellence in plumbing solutions, cast iron remains an undisputed choice, embodying an optimal blend of tradition and innovation in plumbing engineering.

Across industries, the installation ease and versatility of cast iron pipe fittings further enhance their appeal. With standardized sizing and a comprehensive range of connectors, elbows, and reducers, these fittings can be seamlessly integrated into existing systems. Professional installers appreciate the predictability and uniformity of cast iron fittings, which facilitate a smoother installation process and reduce downtime in retrofitting scenarios. In addition, the element of fire resistance offers significant value to cast iron pipe systems, especially in buildings. Unlike plastic counterparts that can melt or emit toxic gases when exposed to high temperatures, cast iron maintains its form, providing an additional safety layer in the event of a fire. This characteristic not only helps in protecting structural integrity but also aids in complying with stringent building codes and safety regulations. Quality assurance and standard compliance are pivotal in the manufacture of cast iron pipe fittings. Leading manufacturers adopt rigorous testing protocols to ensure each fitting not only meets but often exceeds industry standards. These include tests for tensile strength, dimensional accuracy, and hydrostatic pressure resistance. Such diligence in manufacturing not only elevates the performance of the fittings but also instills confidence in consumers and stakeholders relying on these components for critical infrastructure. Moreover, the lifecycle cost benefits of using cast iron pipe fittings cannot be overstated. While the upfront cost may be higher compared to alternatives like PVC or steel, the long-term savings define their true value. Reduced maintenance, lower probability of failure, and minimal replacement needs contribute to a more economical solution over the lifespan of the piping system. In conclusion, cast iron pipe fittings stand as a testament to superior engineering and material science. Their robustness, noise-reduction capabilities, adaptability, and sustainable production methods set them apart in a crowded marketplace. Professionals across the globe continue to specify cast iron pipe fittings for new builds and renovation projects alike, attributed to their proven track record and unmatched performance. For those seeking reliability and excellence in plumbing solutions, cast iron remains an undisputed choice, embodying an optimal blend of tradition and innovation in plumbing engineering.

Next:

Latest news

-

Why Choose TJJ as Your Window and Door Hardware Manufacturer?NewsOct.28,2024

-

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenNewsOct.28,2024

-

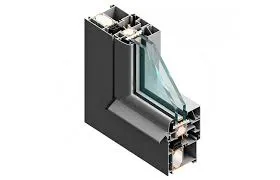

Aluminium Windows Profiles: Benefits and FeaturesNewsOct.28,2024

-

Innovations in Cast Iron Panel TechnologyNewsOct.28,2024

-

The Benefits of Customizing Your Wrought Iron Fence PartsNewsOct.28,2024

-

The Immortal Legacy of Cast Iron Spears: From War to Decorative UseNewsOct.21,2024

-

Why Choose TJJ as Your Window and Door Hardware Manufacturer?Oct-28-2024Why Choose TJJ as Your Window and Door Hardware Manufacturer?

Why Choose TJJ as Your Window and Door Hardware Manufacturer?Oct-28-2024Why Choose TJJ as Your Window and Door Hardware Manufacturer? -

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenOct-28-2024The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your Kitchen

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenOct-28-2024The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your Kitchen -

Aluminium Windows Profiles: Benefits and FeaturesOct-28-2024Aluminium Windows Profiles: Benefits and Features

Aluminium Windows Profiles: Benefits and FeaturesOct-28-2024Aluminium Windows Profiles: Benefits and Features