1 月 . 19, 2025 03:40

Back to list

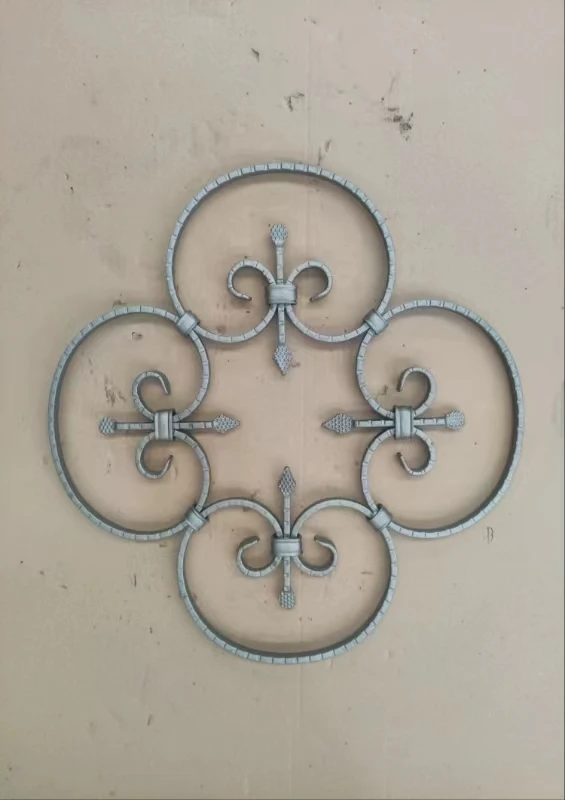

decorative cast iron post collar

Cast iron square collars, a small yet essential component in the world of mechanical engineering and piping systems, have carved a niche for themselves in various industrial applications. Known for their durability and reliability, these collars are indispensable in creating secure joint systems, and their design and material properties speak volumes about their utility in complex setups.

Authoritativeness in this field also comes from an understanding of industry standards and regulations. Cast iron square collars must comply with specific industrial standards like ASTM A126, which outlines the composition and manufacturing guidelines for grey cast iron. This ensures that the materials used are of high quality and capable of withstanding specified conditions. By partnering with manufacturers that adhere to these standards, companies reinforce their commitment to quality and safety. Trustworthiness is further established through rigorous testing and quality assurance of finished products. Reputable suppliers subject their cast iron square collars to various tests — including tensile strength testing, impact resistance trials, and dimensional inspections — to verify that each unit meets both customer quality expectations and safety standards. This thorough vetting process not only guarantees the excellence of the product but also fosters confidence among clients in the long-term reliability of their purchases. Moreover, adopting cast iron square collars aligns with eco-friendly and sustainable practices. Cast iron is often made from recycled materials and is itself fully recyclable, minimizing the environmental footprint associated with its production and use. This factor offers additional reassurance to companies seeking to bolster their sustainability credentials while maintaining high-performance standards in their operational systems. In conclusion, the integration of cast iron square collars into industrial processes is a testament to their exemplary performance and enduring utility. For the seasoned engineer or the meticulous project manager, these components represent more than just a piece of cast metal; they are a cornerstone of structural integrity and efficiency. Whether it be for maintaining pressure systems or ensuring the safety of complex pipelines, cast iron square collars stand out as a reliable choice in the quest for optimization in industrial applications.

Authoritativeness in this field also comes from an understanding of industry standards and regulations. Cast iron square collars must comply with specific industrial standards like ASTM A126, which outlines the composition and manufacturing guidelines for grey cast iron. This ensures that the materials used are of high quality and capable of withstanding specified conditions. By partnering with manufacturers that adhere to these standards, companies reinforce their commitment to quality and safety. Trustworthiness is further established through rigorous testing and quality assurance of finished products. Reputable suppliers subject their cast iron square collars to various tests — including tensile strength testing, impact resistance trials, and dimensional inspections — to verify that each unit meets both customer quality expectations and safety standards. This thorough vetting process not only guarantees the excellence of the product but also fosters confidence among clients in the long-term reliability of their purchases. Moreover, adopting cast iron square collars aligns with eco-friendly and sustainable practices. Cast iron is often made from recycled materials and is itself fully recyclable, minimizing the environmental footprint associated with its production and use. This factor offers additional reassurance to companies seeking to bolster their sustainability credentials while maintaining high-performance standards in their operational systems. In conclusion, the integration of cast iron square collars into industrial processes is a testament to their exemplary performance and enduring utility. For the seasoned engineer or the meticulous project manager, these components represent more than just a piece of cast metal; they are a cornerstone of structural integrity and efficiency. Whether it be for maintaining pressure systems or ensuring the safety of complex pipelines, cast iron square collars stand out as a reliable choice in the quest for optimization in industrial applications.

Latest news

-

Why Choose TJJ as Your Window and Door Hardware Manufacturer?NewsOct.28,2024

-

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenNewsOct.28,2024

-

Aluminium Windows Profiles: Benefits and FeaturesNewsOct.28,2024

-

Innovations in Cast Iron Panel TechnologyNewsOct.28,2024

-

The Benefits of Customizing Your Wrought Iron Fence PartsNewsOct.28,2024

-

The Immortal Legacy of Cast Iron Spears: From War to Decorative UseNewsOct.21,2024

-

Why Choose TJJ as Your Window and Door Hardware Manufacturer?Oct-28-2024Why Choose TJJ as Your Window and Door Hardware Manufacturer?

Why Choose TJJ as Your Window and Door Hardware Manufacturer?Oct-28-2024Why Choose TJJ as Your Window and Door Hardware Manufacturer? -

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenOct-28-2024The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your Kitchen

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenOct-28-2024The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your Kitchen -

Aluminium Windows Profiles: Benefits and FeaturesOct-28-2024Aluminium Windows Profiles: Benefits and Features

Aluminium Windows Profiles: Benefits and FeaturesOct-28-2024Aluminium Windows Profiles: Benefits and Features