Choosing the Right Sliding Door Roller for Smooth and Durable Operation in Your Space

Understanding Sliding Door Floor Rollers A Guide to Functionality and Maintenance

Sliding doors are a popular architectural feature in modern homes and commercial spaces. They not only save space but also provide a seamless transition between indoor and outdoor environments. A crucial component of these sliding mechanisms is the floor rollers. Understanding the functionality and maintenance of sliding door floor rollers can enhance the longevity of your doors and improve their operation.

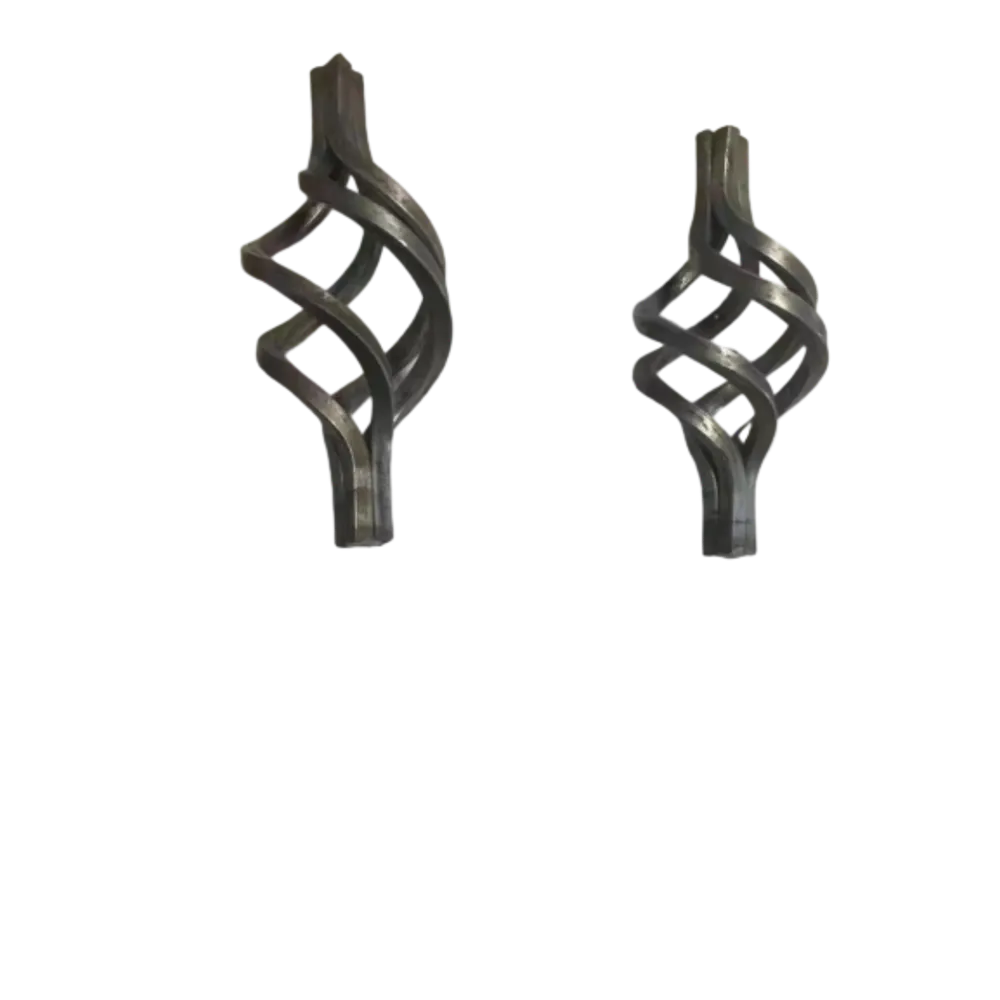

What Are Sliding Door Floor Rollers?

Floor rollers are installed at the bottom of sliding doors, allowing them to glide smoothly along a track. They typically consist of a wheel and support system, designed to bear the weight of the door while allowing it to open and close effortlessly. These rollers can be made from various materials, including plastic and metal, depending on the design of the door and its intended use.

There are two primary types of sliding door rollers the single roller and the dual roller. Single rollers are often used in lightweight doors, whereas dual rollers provide extra stability and load-bearing capacity, making them ideal for heavier doors, such as glass sliding doors.

Benefits of High-Quality Floor Rollers

Investing in high-quality sliding door floor rollers can significantly affect the overall performance of your doors. Good rollers offer smoother operation, reduce noise, and enhance the lifespan of the door components. Cheaper rollers may lead to increased friction, causing wear and tear on the door and track, ultimately resulting in costly repairs or replacements.

Additionally, quality rollers often feature adjustable height settings, which can be beneficial for maintaining the proper alignment of the door over time. A well-aligned sliding door not only operates more smoothly but also contributes to better insulation and security.

Common Issues with Sliding Door Floor Rollers

Despite their durability, sliding door floor rollers can face several issues over time. Common problems include

1. Difficulty in Opening/Closing This is often due to dirt accumulation or misalignment of the track. Regular cleaning of both the rollers and track can help alleviate this issue.

sliding door floor rollers

2. Worn Out Rollers Over time, rollers can wear down and may need to be replaced. Signs of wear include a rough surface or visible cracks.

3. Rust and Corrosion Metal rollers, if not properly coated, can suffer from rust, especially in humid conditions. Rusty rollers can compromise the functionality of the door and may require complete replacements.

4. Noise Excessive noise when sliding the door often indicates that the rollers require lubrication or have collected dirt and debris.

Maintenance Tips for Sliding Door Floor Rollers

To ensure the longevity of your sliding door floor rollers, consider the following maintenance tips

- Regular Cleaning Clean the tracks and rollers at least once every few months. Use a vacuum to remove debris and a damp cloth to wipe down the surfaces.

- Lubrication Apply a silicone-based lubricant to the rollers and track periodically. Avoid using grease, which can attract dust and dirt.

- Check for Alignment Regularly inspect the alignment of the sliding door. If the door appears to be crooked, adjust the rollers as necessary.

- Listen for Problems Pay attention to any unusual sounds when operating the door. Address any noise promptly to prevent further damage.

Conclusion

Sliding door floor rollers play a vital role in the functionality of sliding doors. By understanding how they work and the importance of maintenance, you can ensure the smooth operation of your doors, prolong their lifespan, and maintain the aesthetic appeal of your living or working space. Investing time in the upkeep of these seemingly minor components can yield significant advantages in the long run, enhancing your indoor and outdoor experience.

-

Why Choose TJJ as Your Window and Door Hardware Manufacturer?NewsOct.28,2024

-

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenNewsOct.28,2024

-

Aluminium Windows Profiles: Benefits and FeaturesNewsOct.28,2024

-

Innovations in Cast Iron Panel TechnologyNewsOct.28,2024

-

The Benefits of Customizing Your Wrought Iron Fence PartsNewsOct.28,2024

-

The Immortal Legacy of Cast Iron Spears: From War to Decorative UseNewsOct.21,2024

-

Why Choose TJJ as Your Window and Door Hardware Manufacturer?Oct-28-2024Why Choose TJJ as Your Window and Door Hardware Manufacturer?

Why Choose TJJ as Your Window and Door Hardware Manufacturer?Oct-28-2024Why Choose TJJ as Your Window and Door Hardware Manufacturer? -

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenOct-28-2024The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your Kitchen

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenOct-28-2024The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your Kitchen -

Aluminium Windows Profiles: Benefits and FeaturesOct-28-2024Aluminium Windows Profiles: Benefits and Features

Aluminium Windows Profiles: Benefits and FeaturesOct-28-2024Aluminium Windows Profiles: Benefits and Features