2 月 . 16, 2025 12:17

Back to list

Cast Iron Panel

Wrought iron, known for its malleability and aesthetic appeal, has been a staple in construction, art, and design for centuries. However, an often-asked question is does wrought iron rust? The answer is yes, wrought iron can rust, but understanding the factors involved, as well as the methods of prevention and maintenance, is crucial for making informed decisions about using it in products and projects.

For products incorporating wrought iron, trustworthiness in delivering quality and durability hinges on the adoption of comprehensive maintenance strategies. Regular inspections for any signs of rust or damage, especially in joints and welds, are imperative. Treatments should be reapplied periodically to maintain their protective function, ensuring the longevity and aesthetic integrity of the iron. Real-world applications further illustrate that wrought iron, despite its rusting propensity, remains a popular choice due to its charm and classic appeal. For example, in garden furniture, ornamental gates, and railings, even slight rusting can lend an antiquated look, which is often desirable. However, for structural applications where integrity is paramount, ongoing maintenance is key. In crafting a website that effectively addresses consumer concerns regarding wrought iron, it’s vital to incorporate these insights into the content. Emphasizing the unique visual and structural benefits while providing actionable prevention tips will position your site as a comprehensive resource. Combat common misconceptions by clarifying that while wrought iron can rust, proactive measures significantly enhance its lifespan. In summary, a well-rounded approach that includes experience-backed techniques and expert knowledge will set the foundation for a website that not only answers the pivotal question of wrought iron’s susceptibility to rust but also establishes itself as an authoritative and trustworthy source. Ensuring the content is both informative and solution-oriented will attract and retain visitors, fostering a loyal audience and boosting SEO efficacy.

For products incorporating wrought iron, trustworthiness in delivering quality and durability hinges on the adoption of comprehensive maintenance strategies. Regular inspections for any signs of rust or damage, especially in joints and welds, are imperative. Treatments should be reapplied periodically to maintain their protective function, ensuring the longevity and aesthetic integrity of the iron. Real-world applications further illustrate that wrought iron, despite its rusting propensity, remains a popular choice due to its charm and classic appeal. For example, in garden furniture, ornamental gates, and railings, even slight rusting can lend an antiquated look, which is often desirable. However, for structural applications where integrity is paramount, ongoing maintenance is key. In crafting a website that effectively addresses consumer concerns regarding wrought iron, it’s vital to incorporate these insights into the content. Emphasizing the unique visual and structural benefits while providing actionable prevention tips will position your site as a comprehensive resource. Combat common misconceptions by clarifying that while wrought iron can rust, proactive measures significantly enhance its lifespan. In summary, a well-rounded approach that includes experience-backed techniques and expert knowledge will set the foundation for a website that not only answers the pivotal question of wrought iron’s susceptibility to rust but also establishes itself as an authoritative and trustworthy source. Ensuring the content is both informative and solution-oriented will attract and retain visitors, fostering a loyal audience and boosting SEO efficacy.

Latest news

-

Why Choose TJJ as Your Window and Door Hardware Manufacturer?NewsOct.28,2024

-

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenNewsOct.28,2024

-

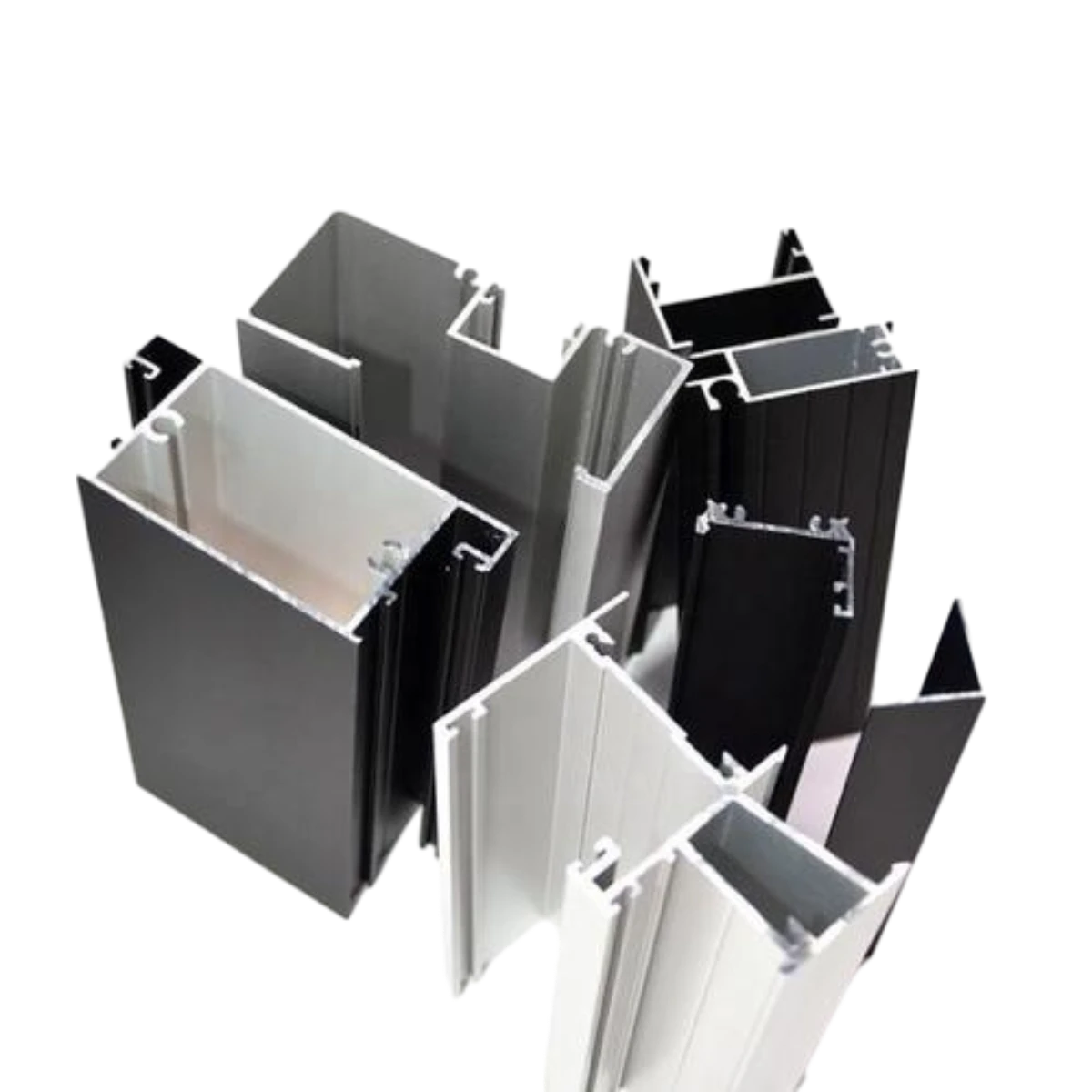

Aluminium Windows Profiles: Benefits and FeaturesNewsOct.28,2024

-

Innovations in Cast Iron Panel TechnologyNewsOct.28,2024

-

The Benefits of Customizing Your Wrought Iron Fence PartsNewsOct.28,2024

-

The Immortal Legacy of Cast Iron Spears: From War to Decorative UseNewsOct.21,2024

-

Why Choose TJJ as Your Window and Door Hardware Manufacturer?Oct-28-2024Why Choose TJJ as Your Window and Door Hardware Manufacturer?

Why Choose TJJ as Your Window and Door Hardware Manufacturer?Oct-28-2024Why Choose TJJ as Your Window and Door Hardware Manufacturer? -

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenOct-28-2024The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your Kitchen

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenOct-28-2024The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your Kitchen -

Aluminium Windows Profiles: Benefits and FeaturesOct-28-2024Aluminium Windows Profiles: Benefits and Features

Aluminium Windows Profiles: Benefits and FeaturesOct-28-2024Aluminium Windows Profiles: Benefits and Features