2 月 . 10, 2025 10:30

Back to list

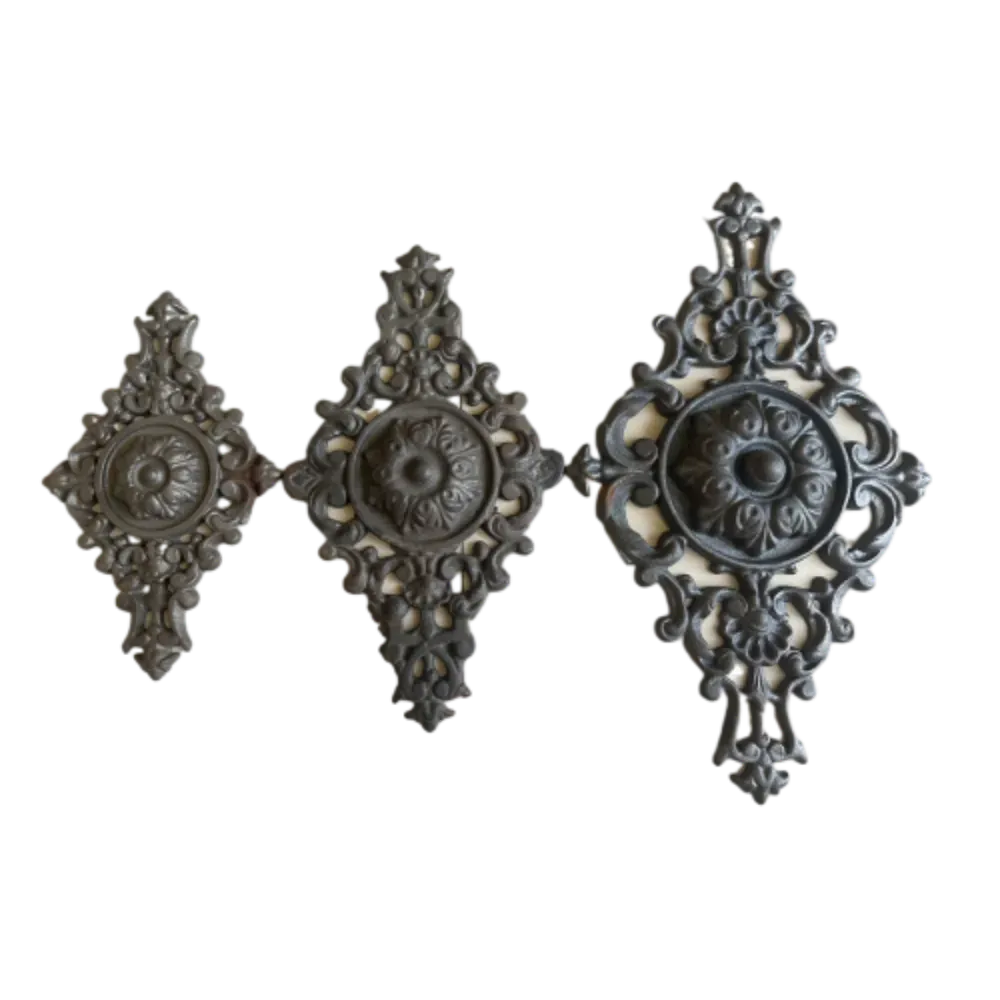

Cast Iron Post Caps

Gate door rollers are essential components in the smooth operation of gates, particularly sliding gates often found in residential, commercial, and industrial settings. As an expert in the field of gate mechanics with years of experience, I aim to highlight not only the technical aspects of gate door rollers but also the nuanced expertise required in selecting and maintaining these crucial items.

Trustworthiness in a gate system is established through consistent maintenance of its components, including gate door rollers. Periodic inspection should be conducted to check for signs of wear, such as cracks or flattened edges, which may inhibit their function. Regular lubrication of the rollers is also essential, as this minimizes friction and prevents them from seizing. By implementing scheduled maintenance, the overall life span of the gate system is prolonged, ensuring continued security and ease of use. Moreover, high-quality rollers sourced from reputable manufacturers guarantee not only smoother operation but also align with industry standards for safety and durability. As an authority in gate mechanics, I cannot stress enough the importance of sourcing components from trusted suppliers who provide warranties and can demonstrate compliance with relevant certifications. This not only assures the performance integrity of the rollers but also upholds the safety of the entire gate system. Consultation with professionals when installing or replacing gate door rollers is vital to ensure proper alignment and function. Incorrect installation can lead to misaligned gates that hinder entrance effectiveness and could potentially pose safety risks. An experienced technician's expertise is indispensable in achieving and maintaining the optimal functionality of the gate system. In conclusion, gate door rollers are small yet exceedingly critical components in a sliding gate system, significantly influencing its operation and longevity. Selecting high-quality rollers, paired with diligent maintenance, assures continuous, reliable performance. Expertise in materials, sizes, and professional installation underscores their importance in the broader context of gate security and operation. By valuing experience, professionalism, authority, and trustworthiness in the upkeep of gate door rollers, property owners can ensure their gates will serve them well for years to come.

Trustworthiness in a gate system is established through consistent maintenance of its components, including gate door rollers. Periodic inspection should be conducted to check for signs of wear, such as cracks or flattened edges, which may inhibit their function. Regular lubrication of the rollers is also essential, as this minimizes friction and prevents them from seizing. By implementing scheduled maintenance, the overall life span of the gate system is prolonged, ensuring continued security and ease of use. Moreover, high-quality rollers sourced from reputable manufacturers guarantee not only smoother operation but also align with industry standards for safety and durability. As an authority in gate mechanics, I cannot stress enough the importance of sourcing components from trusted suppliers who provide warranties and can demonstrate compliance with relevant certifications. This not only assures the performance integrity of the rollers but also upholds the safety of the entire gate system. Consultation with professionals when installing or replacing gate door rollers is vital to ensure proper alignment and function. Incorrect installation can lead to misaligned gates that hinder entrance effectiveness and could potentially pose safety risks. An experienced technician's expertise is indispensable in achieving and maintaining the optimal functionality of the gate system. In conclusion, gate door rollers are small yet exceedingly critical components in a sliding gate system, significantly influencing its operation and longevity. Selecting high-quality rollers, paired with diligent maintenance, assures continuous, reliable performance. Expertise in materials, sizes, and professional installation underscores their importance in the broader context of gate security and operation. By valuing experience, professionalism, authority, and trustworthiness in the upkeep of gate door rollers, property owners can ensure their gates will serve them well for years to come.

Next:

Latest news

-

Why Choose TJJ as Your Window and Door Hardware Manufacturer?NewsOct.28,2024

-

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenNewsOct.28,2024

-

Aluminium Windows Profiles: Benefits and FeaturesNewsOct.28,2024

-

Innovations in Cast Iron Panel TechnologyNewsOct.28,2024

-

The Benefits of Customizing Your Wrought Iron Fence PartsNewsOct.28,2024

-

The Immortal Legacy of Cast Iron Spears: From War to Decorative UseNewsOct.21,2024

-

Why Choose TJJ as Your Window and Door Hardware Manufacturer?Oct-28-2024Why Choose TJJ as Your Window and Door Hardware Manufacturer?

Why Choose TJJ as Your Window and Door Hardware Manufacturer?Oct-28-2024Why Choose TJJ as Your Window and Door Hardware Manufacturer? -

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenOct-28-2024The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your Kitchen

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenOct-28-2024The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your Kitchen -

Aluminium Windows Profiles: Benefits and FeaturesOct-28-2024Aluminium Windows Profiles: Benefits and Features

Aluminium Windows Profiles: Benefits and FeaturesOct-28-2024Aluminium Windows Profiles: Benefits and Features