gate welding

Gate Welding A Comprehensive Guide

Gate welding is a crucial process in the fabrication and construction of gates for various purposes, including residential, commercial, and industrial settings. Welding offers a robust solution for creating durable, secure, and aesthetically pleasing gates that can withstand various environmental challenges. This article delves into the fundamentals of gate welding, its benefits, techniques, and essential safety measures.

Welding is the process of joining two or more pieces of material, typically metal, by applying heat and sometimes pressure. It is a favored method for gate construction due to its ability to create strong, permanent bonds. Common materials used in gate welding include steel, aluminum, and wrought iron. Each material has its unique properties, influencing the welding technique chosen.

One of the primary techniques employed in gate welding is MIG (Metal Inert Gas) welding. This process involves feeding a continuous solid wire electrode through a welding gun while shielding the weld area with an inert gas to protect it from contamination. MIG welding is popular due to its versatility, speed, and ease of use, making it ideal for both professional welders and DIY enthusiasts.

gate welding

Another technique is TIG (Tungsten Inert Gas) welding, which offers greater precision and control. Suitable for thinner materials, TIG welding uses a non-consumable tungsten electrode to produce the weld, requiring a skilled hand to execute effectively. Although it may take longer than MIG welding, the quality of the weld produced is often superior, making it a preferred choice for intricate designs and detailed work.

Gate welding offers several advantages. Firstly, welded gates provide exceptional strength and longevity compared to other joining methods like bolting or riveting. This durability ensures that gates can resist bending, warping, and rusting, making them suitable for various climates and conditions. Additionally, welded gates can be designed in numerous styles and shapes, allowing for both functional security and aesthetic appeal.

Safety is paramount during the gate welding process. Welders should always wear proper protective gear, including helmets with appropriate shading, gloves, and fire-resistant clothing. Adequate ventilation is essential to prevent exposure to harmful fumes and gases produced during welding. Moreover, ensuring a clean and organized workspace is vital to minimize hazards and improve efficiency.

In conclusion, gate welding is an essential practice in constructing secure and visually appealing gates. With various techniques available, welders can choose methods that best suit their materials and design requirements. The benefits of gate welding, including strength, durability, and design versatility, make it a preferred choice for many projects. By adhering to safety precautions, welders can effectively create gates that not only meet functional requirements but also enhance the overall aesthetic of their surroundings.

-

Why Choose TJJ as Your Window and Door Hardware Manufacturer?NewsOct.28,2024

-

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenNewsOct.28,2024

-

Aluminium Windows Profiles: Benefits and FeaturesNewsOct.28,2024

-

Innovations in Cast Iron Panel TechnologyNewsOct.28,2024

-

The Benefits of Customizing Your Wrought Iron Fence PartsNewsOct.28,2024

-

The Immortal Legacy of Cast Iron Spears: From War to Decorative UseNewsOct.21,2024

-

Why Choose TJJ as Your Window and Door Hardware Manufacturer?Oct-28-2024Why Choose TJJ as Your Window and Door Hardware Manufacturer?

Why Choose TJJ as Your Window and Door Hardware Manufacturer?Oct-28-2024Why Choose TJJ as Your Window and Door Hardware Manufacturer? -

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenOct-28-2024The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your Kitchen

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenOct-28-2024The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your Kitchen -

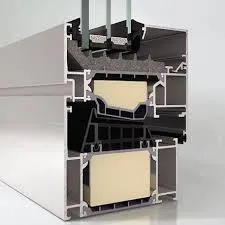

Aluminium Windows Profiles: Benefits and FeaturesOct-28-2024Aluminium Windows Profiles: Benefits and Features

Aluminium Windows Profiles: Benefits and FeaturesOct-28-2024Aluminium Windows Profiles: Benefits and Features