3 月 . 07, 2025 00:55

Back to list

grain peeler machine

When envisioning the seamless operation of grain processing, a pivotal component quietly revolutionizing the industry is the grain peeler machine. Often overshadowed by more sophisticated machinery, this deceptively simple device holds unparalleled significance in delivering high-quality, prepared grains to the global market. From small-scale farmers to massive agricultural enterprises, the grain peeler machine stands as a cornerstone of efficiency, precision, and quality assurance.

Trustworthiness comes from proven performance and reliability. Leading manufacturers stand by their products, offering extensive warranties and customer support services. This commitment to customer satisfaction is not just about post-purchase assistance but reflects the confidence manufacturers have in their machinery's performance. Farm operators report significantly reduced downtime and maintenance with these machines, further solidifying their status as a trustworthy investment. Moreover, testimonials from a plethora of satisfied users across continents highlight the grain peeler machine's role in revolutionizing their grain preparation processes. Furthermore, with the world's increasing focus on sustainability and efficient resource use, grain peeler machines are now more crucial than ever. Their ability to significantly reduce grain wastage aligns with global efforts to enhance food security and sustainable agriculture practices. By optimizing the production process, these machines contribute to a greener, more accountable farm-to-table journey, satisfying both regulatory requirements and consumer expectations for environmentally responsible farming practices. In sum, the grain peeler machine stands as a paradigm of innovation marrying experience, expertise, authoritativeness, and trustworthiness within the agricultural sphere. As the world continues to evolve, so will the technologies surrounding grain processing, with the grain peeler machine remaining central in ensuring that the grains reaching our tables are of the highest quality. For any agricultural entity—be it a small farm or a large industrial complex—incorporating a grain peeler machine is not just an investment in machinery, but an investment in the future of food production, efficiency, and sustainability.

Trustworthiness comes from proven performance and reliability. Leading manufacturers stand by their products, offering extensive warranties and customer support services. This commitment to customer satisfaction is not just about post-purchase assistance but reflects the confidence manufacturers have in their machinery's performance. Farm operators report significantly reduced downtime and maintenance with these machines, further solidifying their status as a trustworthy investment. Moreover, testimonials from a plethora of satisfied users across continents highlight the grain peeler machine's role in revolutionizing their grain preparation processes. Furthermore, with the world's increasing focus on sustainability and efficient resource use, grain peeler machines are now more crucial than ever. Their ability to significantly reduce grain wastage aligns with global efforts to enhance food security and sustainable agriculture practices. By optimizing the production process, these machines contribute to a greener, more accountable farm-to-table journey, satisfying both regulatory requirements and consumer expectations for environmentally responsible farming practices. In sum, the grain peeler machine stands as a paradigm of innovation marrying experience, expertise, authoritativeness, and trustworthiness within the agricultural sphere. As the world continues to evolve, so will the technologies surrounding grain processing, with the grain peeler machine remaining central in ensuring that the grains reaching our tables are of the highest quality. For any agricultural entity—be it a small farm or a large industrial complex—incorporating a grain peeler machine is not just an investment in machinery, but an investment in the future of food production, efficiency, and sustainability.

Next:

Latest news

-

Why Choose TJJ as Your Window and Door Hardware Manufacturer?NewsOct.28,2024

-

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenNewsOct.28,2024

-

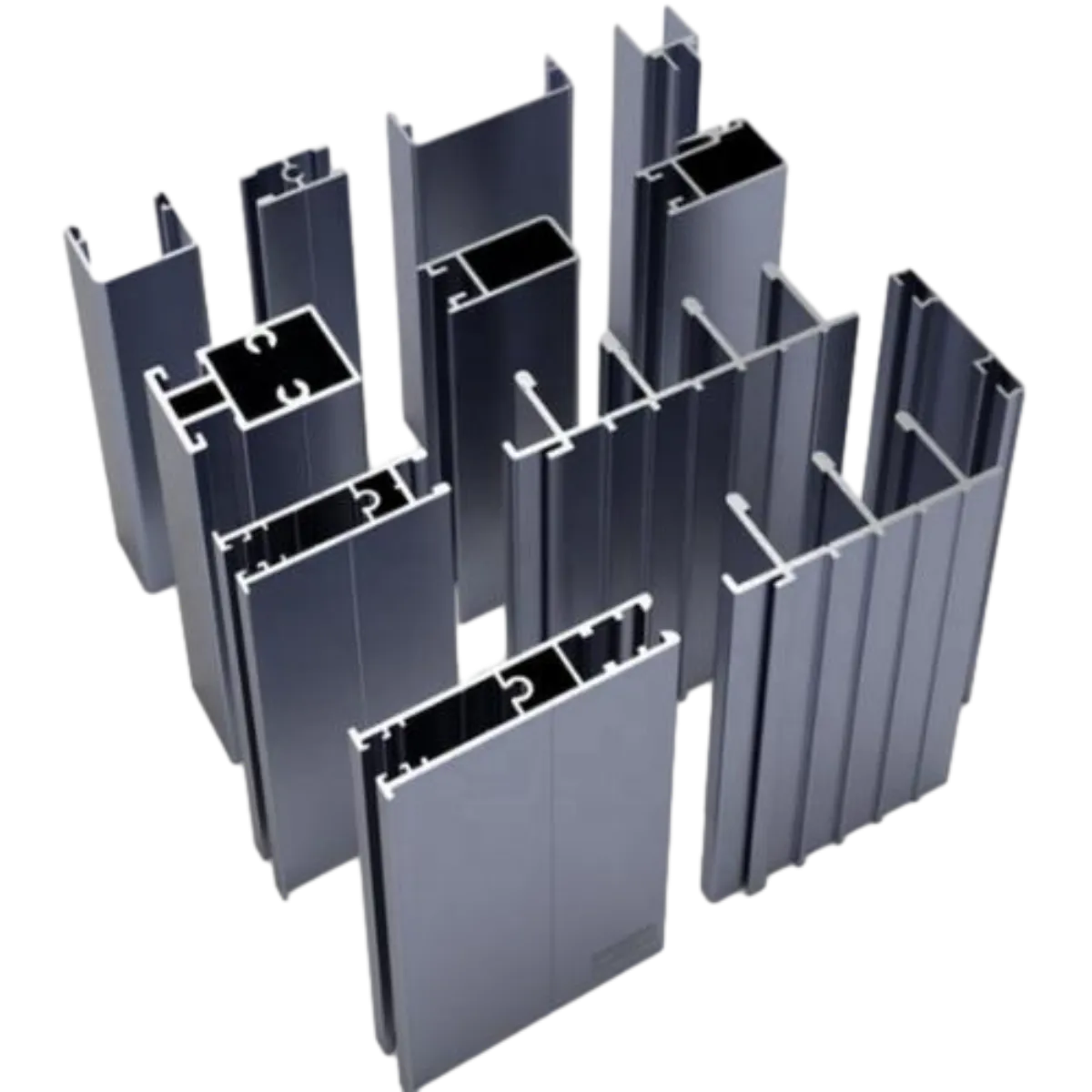

Aluminium Windows Profiles: Benefits and FeaturesNewsOct.28,2024

-

Innovations in Cast Iron Panel TechnologyNewsOct.28,2024

-

The Benefits of Customizing Your Wrought Iron Fence PartsNewsOct.28,2024

-

The Immortal Legacy of Cast Iron Spears: From War to Decorative UseNewsOct.21,2024

-

Why Choose TJJ as Your Window and Door Hardware Manufacturer?Oct-28-2024Why Choose TJJ as Your Window and Door Hardware Manufacturer?

Why Choose TJJ as Your Window and Door Hardware Manufacturer?Oct-28-2024Why Choose TJJ as Your Window and Door Hardware Manufacturer? -

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenOct-28-2024The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your Kitchen

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenOct-28-2024The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your Kitchen -

Aluminium Windows Profiles: Benefits and FeaturesOct-28-2024Aluminium Windows Profiles: Benefits and Features

Aluminium Windows Profiles: Benefits and FeaturesOct-28-2024Aluminium Windows Profiles: Benefits and Features