2 月 . 05, 2025 03:44

Back to list

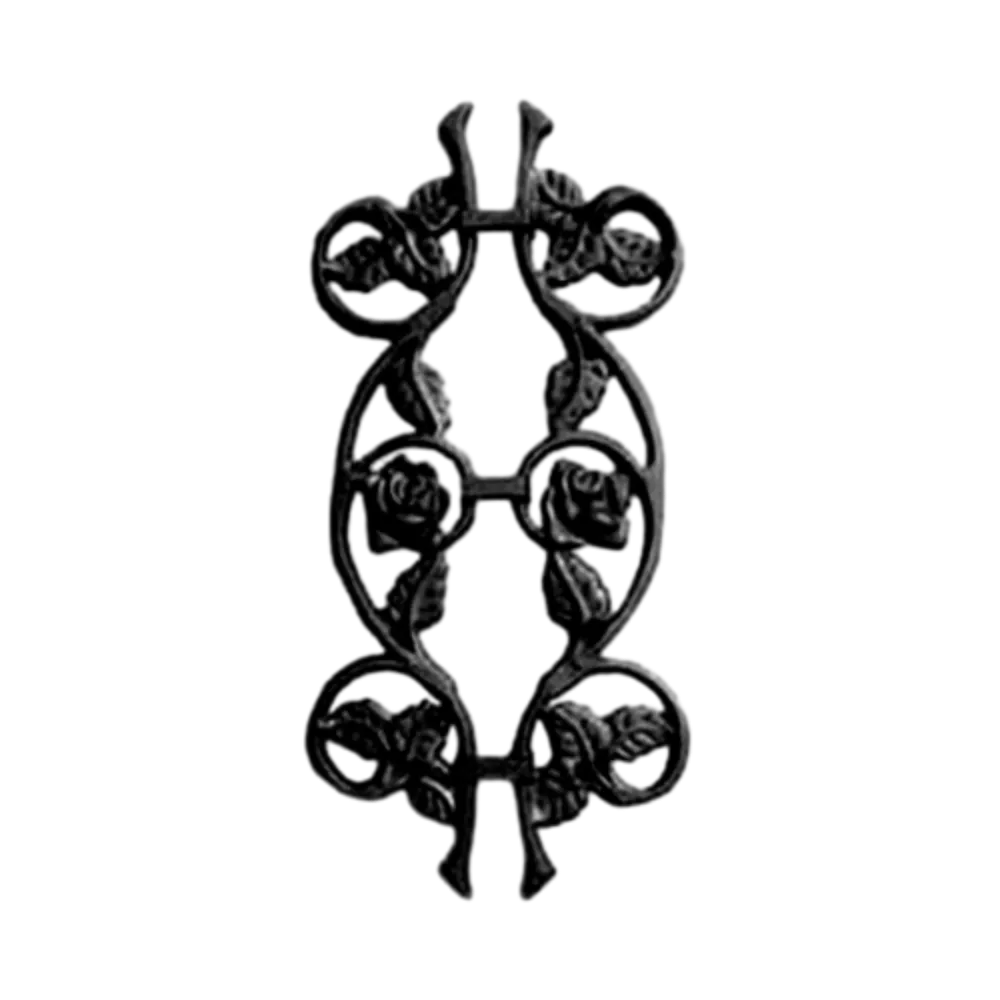

cast iron decorative panels

Heavy door rollers are essential components in a variety of settings, from industrial complexes to luxury residential properties. These small but mighty elements play a crucial role in ensuring the smooth and efficient operation of heavy doors, whether they are part of a large warehouse, a high-end condominium, or a state-of-the-art manufacturing facility.

In terms of installation and maintenance, trustworthiness of a product is often measured by its ease of use and long-term performance. Installers prefer products that come with comprehensive, intuitive instructions and components that fit seamlessly with a wide array of door designs. Maintenance considerations include the availability of easily replaceable parts and resistance to factors like rust, that can compromise the function of rollers over time. High-quality heavy door rollers often feature sealed bearings which require minimal maintenance while prolonging the operational life of the door system. From an expertise standpoint, it’s essential to understand the engineering principles behind heavy door rollers. This involves the dynamics of weight distribution and the friction-reducing properties that these components offer. Doors equipped with top-tier rollers glide effortlessly, reducing stress on door motors and manual efforts alike. This efficiency not only saves time and energy but also minimizes sound, which is crucial in environments where noise pollution is a concern. The importance of trustworthiness cannot be overstated. Purchasing decisions must be informed by user reviews, warranty options, and the track record of manufacturers in the industry. Couple this with input from industry professionals—those who have installed these systems in various settings and have first-hand knowledge of performance under different conditions—and you can confidently select high-performance heavy door rollers that meet and exceed expectations. In conclusion, heavy door rollers are critical components in ensuring the function and safety of heavy doors. Their selection should be governed by an understanding of load requirements, material needs, and performance expectations. Expertise in their installation and maintenance ensures their longevity, while authoritativeness in product choice and brand selection guarantees optimal performance. A focus on trustworthiness reaffirms a commitment to quality, safety, and durability—key factors in making an informed and confident purchase.

In terms of installation and maintenance, trustworthiness of a product is often measured by its ease of use and long-term performance. Installers prefer products that come with comprehensive, intuitive instructions and components that fit seamlessly with a wide array of door designs. Maintenance considerations include the availability of easily replaceable parts and resistance to factors like rust, that can compromise the function of rollers over time. High-quality heavy door rollers often feature sealed bearings which require minimal maintenance while prolonging the operational life of the door system. From an expertise standpoint, it’s essential to understand the engineering principles behind heavy door rollers. This involves the dynamics of weight distribution and the friction-reducing properties that these components offer. Doors equipped with top-tier rollers glide effortlessly, reducing stress on door motors and manual efforts alike. This efficiency not only saves time and energy but also minimizes sound, which is crucial in environments where noise pollution is a concern. The importance of trustworthiness cannot be overstated. Purchasing decisions must be informed by user reviews, warranty options, and the track record of manufacturers in the industry. Couple this with input from industry professionals—those who have installed these systems in various settings and have first-hand knowledge of performance under different conditions—and you can confidently select high-performance heavy door rollers that meet and exceed expectations. In conclusion, heavy door rollers are critical components in ensuring the function and safety of heavy doors. Their selection should be governed by an understanding of load requirements, material needs, and performance expectations. Expertise in their installation and maintenance ensures their longevity, while authoritativeness in product choice and brand selection guarantees optimal performance. A focus on trustworthiness reaffirms a commitment to quality, safety, and durability—key factors in making an informed and confident purchase.

Next:

Latest news

-

Why Choose TJJ as Your Window and Door Hardware Manufacturer?NewsOct.28,2024

-

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenNewsOct.28,2024

-

Aluminium Windows Profiles: Benefits and FeaturesNewsOct.28,2024

-

Innovations in Cast Iron Panel TechnologyNewsOct.28,2024

-

The Benefits of Customizing Your Wrought Iron Fence PartsNewsOct.28,2024

-

The Immortal Legacy of Cast Iron Spears: From War to Decorative UseNewsOct.21,2024

-

Why Choose TJJ as Your Window and Door Hardware Manufacturer?Oct-28-2024Why Choose TJJ as Your Window and Door Hardware Manufacturer?

Why Choose TJJ as Your Window and Door Hardware Manufacturer?Oct-28-2024Why Choose TJJ as Your Window and Door Hardware Manufacturer? -

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenOct-28-2024The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your Kitchen

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenOct-28-2024The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your Kitchen -

Aluminium Windows Profiles: Benefits and FeaturesOct-28-2024Aluminium Windows Profiles: Benefits and Features

Aluminium Windows Profiles: Benefits and FeaturesOct-28-2024Aluminium Windows Profiles: Benefits and Features