1 月 . 20, 2025 03:54

Back to list

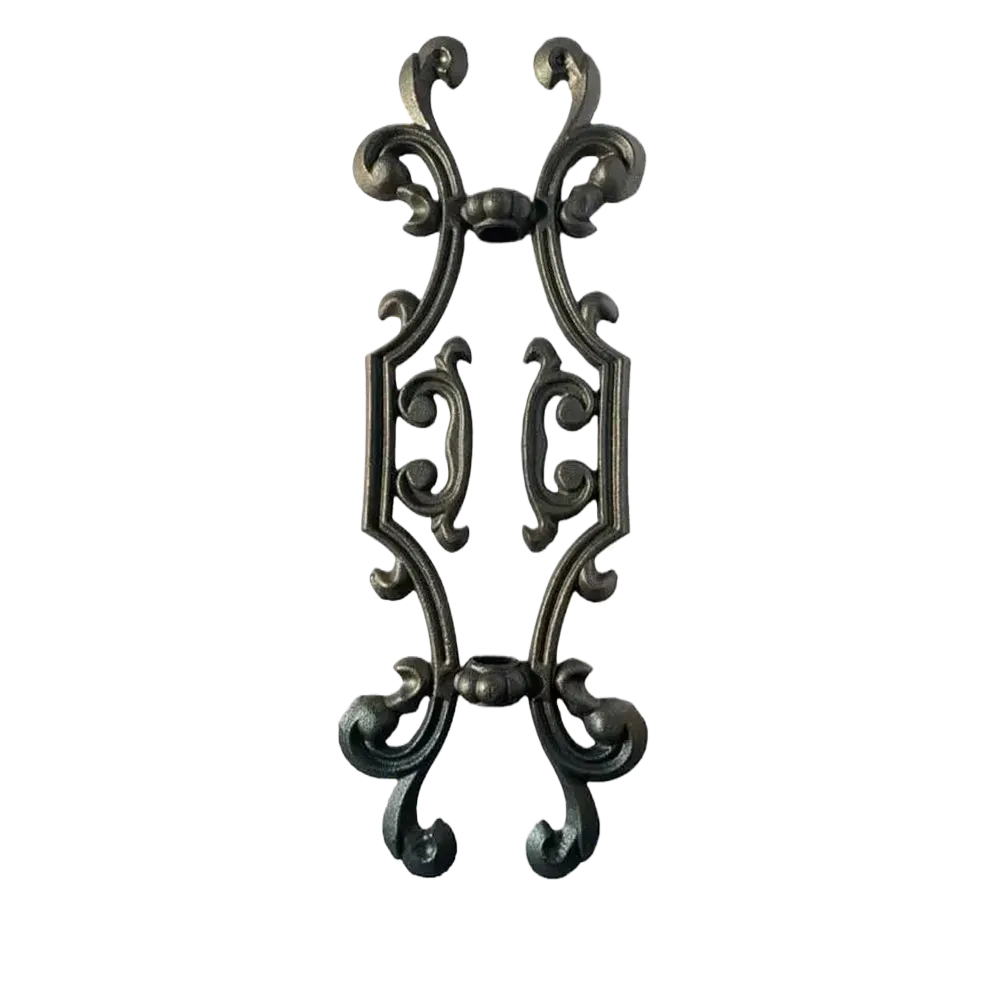

Cast Iron Post Caps/Gate Tops

Heavy duty barrel hinges are essential components in industrial applications requiring robust and reliable pivot joints. These hinges, renowned for their durability and strength, are frequently utilized in gates, doors, and other heavy-duty installations where strength and longevity are paramount.

Trustworthiness is demonstrated through transparent communication about the hinge's capabilities and limitations. For example, manufacturers and suppliers often provide detailed specification sheets, installation guides, and customer testimonials. This information helps ensure that buyers are fully informed about product features, enabling them to make choices that align with their specific application needs. The integration of cutting-edge technology has also enhanced the functionality of heavy duty barrel hinges. Innovations such as self-lubricating bearings and adjustable tension systems have improved operational efficiency and reduced maintenance requirements. These features allow for smoother operation under heavy loads and extend the hinge’s life, thereby reducing long-term costs for users. Finally, choosing a reputable supplier is critical when sourcing heavy duty barrel hinges. Potential buyers should seek out companies with a proven track record in producing high-quality industrial products. Reviews from past customers, industry awards, and certifications can provide insights into a supplier’s reputation and the reliability of their products. In summary, heavy duty barrel hinges are indispensable in applications that require enduring strength and reliability. By understanding the nuances of their design, installation, and maintenance, stakeholders can ensure that they select the most suitable hinges for their specific needs. As advancements continue in material science and engineering, these hinges will only grow more efficient and reliable, solidifying their role in critical industrial applications.

Trustworthiness is demonstrated through transparent communication about the hinge's capabilities and limitations. For example, manufacturers and suppliers often provide detailed specification sheets, installation guides, and customer testimonials. This information helps ensure that buyers are fully informed about product features, enabling them to make choices that align with their specific application needs. The integration of cutting-edge technology has also enhanced the functionality of heavy duty barrel hinges. Innovations such as self-lubricating bearings and adjustable tension systems have improved operational efficiency and reduced maintenance requirements. These features allow for smoother operation under heavy loads and extend the hinge’s life, thereby reducing long-term costs for users. Finally, choosing a reputable supplier is critical when sourcing heavy duty barrel hinges. Potential buyers should seek out companies with a proven track record in producing high-quality industrial products. Reviews from past customers, industry awards, and certifications can provide insights into a supplier’s reputation and the reliability of their products. In summary, heavy duty barrel hinges are indispensable in applications that require enduring strength and reliability. By understanding the nuances of their design, installation, and maintenance, stakeholders can ensure that they select the most suitable hinges for their specific needs. As advancements continue in material science and engineering, these hinges will only grow more efficient and reliable, solidifying their role in critical industrial applications.

Next:

Latest news

-

Why Choose TJJ as Your Window and Door Hardware Manufacturer?NewsOct.28,2024

-

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenNewsOct.28,2024

-

Aluminium Windows Profiles: Benefits and FeaturesNewsOct.28,2024

-

Innovations in Cast Iron Panel TechnologyNewsOct.28,2024

-

The Benefits of Customizing Your Wrought Iron Fence PartsNewsOct.28,2024

-

The Immortal Legacy of Cast Iron Spears: From War to Decorative UseNewsOct.21,2024

-

Why Choose TJJ as Your Window and Door Hardware Manufacturer?Oct-28-2024Why Choose TJJ as Your Window and Door Hardware Manufacturer?

Why Choose TJJ as Your Window and Door Hardware Manufacturer?Oct-28-2024Why Choose TJJ as Your Window and Door Hardware Manufacturer? -

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenOct-28-2024The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your Kitchen

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenOct-28-2024The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your Kitchen -

Aluminium Windows Profiles: Benefits and FeaturesOct-28-2024Aluminium Windows Profiles: Benefits and Features

Aluminium Windows Profiles: Benefits and FeaturesOct-28-2024Aluminium Windows Profiles: Benefits and Features