2 月 . 19, 2025 10:48

Back to list

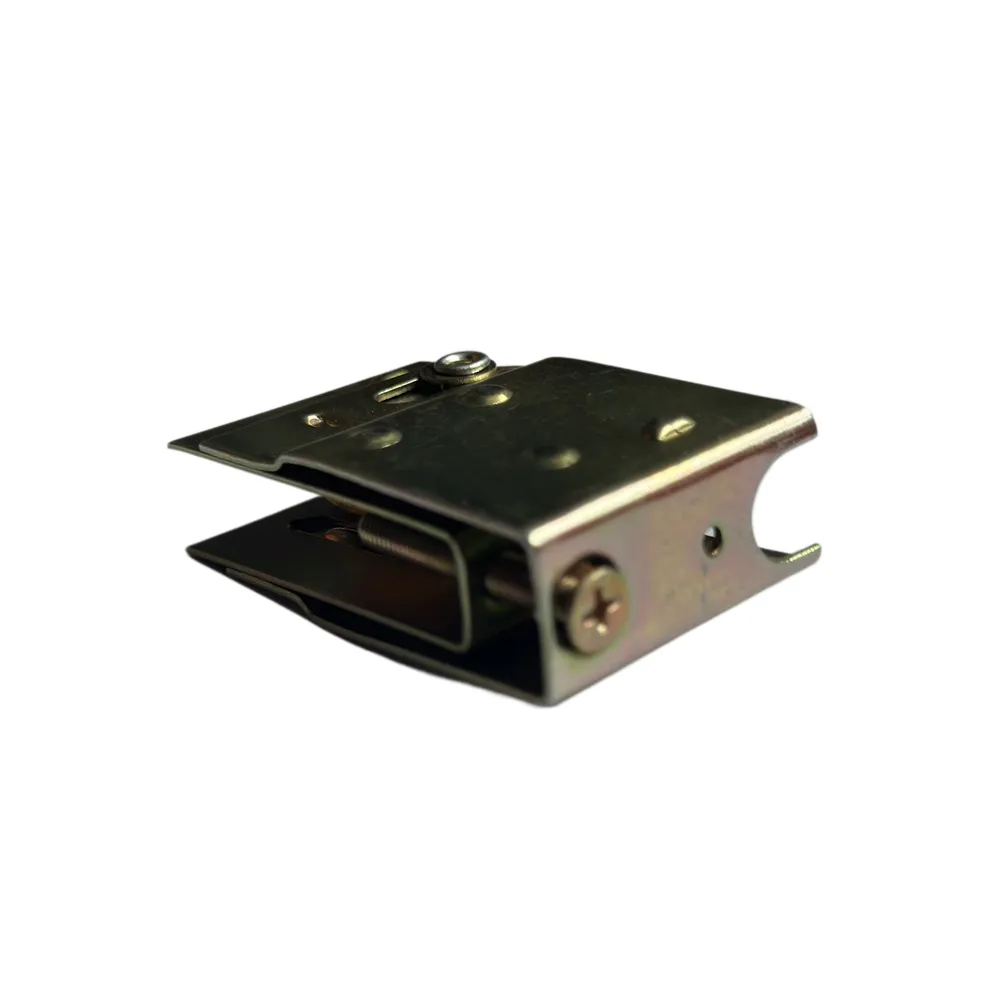

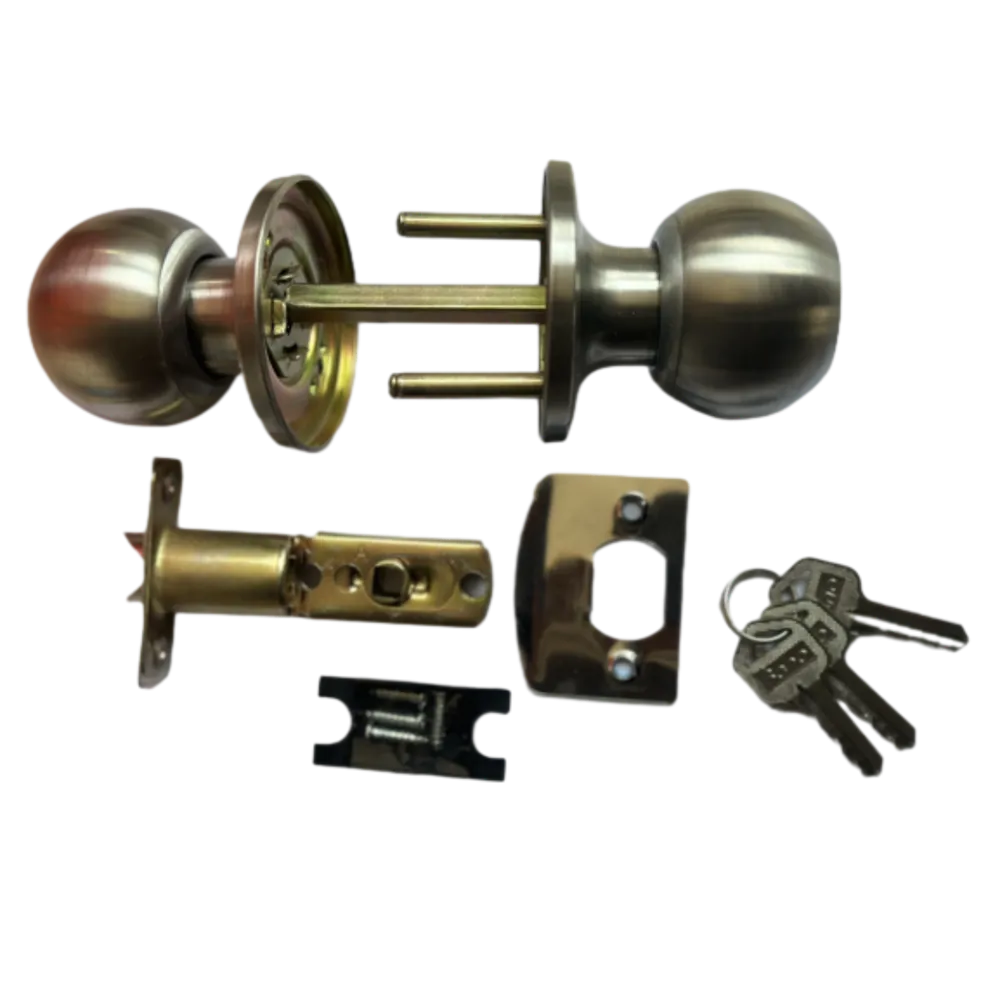

lock-lock boxes

High-quality metal hollow balls continue to revolutionize industries thanks to their unique combination of strength, versatility, and lightweight properties. When it comes to the needs of various industries such as construction, automotive, and decorative arts, these spherical marvels offer unparalleled benefits that merit exploration by manufacturers, designers, and engineers alike.

From a precision engineering perspective, the production of high-quality metal hollow balls demands expertise and precision. Manufacturing processes such as metal spinning, stamping, or hydroforming require skilled craftsmanship to ensure that each ball meets the exact specifications needed for its intended application. This precision ensures that the spheres maintain consistent thickness and structural integrity, which is vital for their performance in stress-bearing applications. The high level of expertise involved underlines the authoritative nature of metal hollow ball manufacturers who guarantee performance and precision across diverse industries. Market demand for quality and innovative solutions is ever-increasing, and metal hollow balls serve as a testament to human ingenuity in meeting these evolving industrial needs. Their adaptability to various forms – from their use in load-disbearing structures to decorative accents – highlights their multifaceted utility. The trust that engineers and designers place in metal hollow balls is evidence of their effective combination of technology, durability, and design. In conclusion, metal hollow balls stand as essential components in the toolbox of modern industry professionals. They embody experience in engineering, authoritative production standards, and a commitment to quality and sustainability. As industries continue to evolve, those who harness the potential of metal hollow balls are sure to find themselves at the forefront of innovation. Whether used in construction, automotive, or design, the strategic employment of metal hollow balls is undeniably an advantage worth pursuing for those seeking to ensure efficiency and innovation in their projects.

From a precision engineering perspective, the production of high-quality metal hollow balls demands expertise and precision. Manufacturing processes such as metal spinning, stamping, or hydroforming require skilled craftsmanship to ensure that each ball meets the exact specifications needed for its intended application. This precision ensures that the spheres maintain consistent thickness and structural integrity, which is vital for their performance in stress-bearing applications. The high level of expertise involved underlines the authoritative nature of metal hollow ball manufacturers who guarantee performance and precision across diverse industries. Market demand for quality and innovative solutions is ever-increasing, and metal hollow balls serve as a testament to human ingenuity in meeting these evolving industrial needs. Their adaptability to various forms – from their use in load-disbearing structures to decorative accents – highlights their multifaceted utility. The trust that engineers and designers place in metal hollow balls is evidence of their effective combination of technology, durability, and design. In conclusion, metal hollow balls stand as essential components in the toolbox of modern industry professionals. They embody experience in engineering, authoritative production standards, and a commitment to quality and sustainability. As industries continue to evolve, those who harness the potential of metal hollow balls are sure to find themselves at the forefront of innovation. Whether used in construction, automotive, or design, the strategic employment of metal hollow balls is undeniably an advantage worth pursuing for those seeking to ensure efficiency and innovation in their projects.

Next:

Latest news

-

Why Choose TJJ as Your Window and Door Hardware Manufacturer?NewsOct.28,2024

-

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenNewsOct.28,2024

-

Aluminium Windows Profiles: Benefits and FeaturesNewsOct.28,2024

-

Innovations in Cast Iron Panel TechnologyNewsOct.28,2024

-

The Benefits of Customizing Your Wrought Iron Fence PartsNewsOct.28,2024

-

The Immortal Legacy of Cast Iron Spears: From War to Decorative UseNewsOct.21,2024

-

Why Choose TJJ as Your Window and Door Hardware Manufacturer?Oct-28-2024Why Choose TJJ as Your Window and Door Hardware Manufacturer?

Why Choose TJJ as Your Window and Door Hardware Manufacturer?Oct-28-2024Why Choose TJJ as Your Window and Door Hardware Manufacturer? -

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenOct-28-2024The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your Kitchen

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenOct-28-2024The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your Kitchen -

Aluminium Windows Profiles: Benefits and FeaturesOct-28-2024Aluminium Windows Profiles: Benefits and Features

Aluminium Windows Profiles: Benefits and FeaturesOct-28-2024Aluminium Windows Profiles: Benefits and Features