Metal Sheets Ideal for Welding Projects and Fabrication Techniques

Metal Leaves for Welding A Comprehensive Guide

Welding is a fundamental technique in metallurgy and manufacturing, allowing for the joining of various metals to create strong, enduring structures. Among the many materials used in welding, metal leaves offer unique advantages that can enhance the quality and efficiency of welding projects. In this article, we will delve into the benefits, applications, and best practices of using metal leaves for welding.

What Are Metal Leaves?

Metal leaves are thin sheets or foils made from various metals such as steel, aluminum, copper, and brass. These leaves come in different thicknesses, typically ranging from 0.001 to 0.1 inches, making them versatile for various applications. Their thin profile allows for exceptional flexibility and ease of manipulation, making them ideal for intricate welding projects.

Benefits of Using Metal Leaves for Welding

1. Lightweight and Versatile Metal leaves are lightweight, making them easier to transport and handle during the welding process. Their versatility allows them to be used in a wide range of applications, from aerospace to artistic sculptures.

2. Precision and Detailing The thin nature of metal leaves enables welders to achieve high precision in their work. This level of detail is particularly beneficial in artistic welding projects where intricate designs are required.

3. Cost-Effective Using metal leaves can be more economical than working with thicker plates or sheets. They require less material and often result in less waste during the welding process, which can significantly reduce costs.

4. Enhanced Welding Techniques Metal leaves can accompany advanced welding techniques, such as laser welding or TIG welding, which require precise application and control. This compatibility allows for a wider array of projects that demand high-quality results.

Applications of Metal Leaves in Welding

The applications for metal leaves in welding are diverse. Here are a few notable examples

1. Artistic Sculptures Artists often use metal leaves to create stunning sculptures that showcase their creativity. The ability to manipulate and weld intricate designs fosters artistic expression.

metal leaves for welding

2. Aerospace Components The aerospace industry frequently uses metal leaves to manufacture lightweight components crucial for aircraft performance and fuel efficiency.

3. Automotive Industry Metal leaves are utilized in the construction of car parts, providing strength while keeping the overall weight of the vehicle down.

4. Electronics In the electronics sector, metal leaves are used in the production of thin, conductive layers that are essential for circuit boards and other electronic components.

Best Practices for Welding with Metal Leaves

To achieve optimal results when welding with metal leaves, consider the following best practices

1. Proper Equipment Utilize equipment suited for thin materials, such as a TIG welder or laser welder, as these tools provide better control and precision.

2. Select the Right Filler Material Choose a filler material that matches the composition of the metal leaves being welded to ensure a strong joint and avoid corrosion.

3. Control Heat Input Be cautious of the heat input, as excessive heat can lead to warping or burning through the thin material. Start with lower amperage settings and gradually increase as needed.

4. Clean the Surface Before welding, clean the metal leaves thoroughly to remove any contaminants. A clean surface helps ensure better weld penetration and reduces the risk of defects.

Conclusion

Metal leaves for welding present a unique opportunity for welders, artists, and manufacturers alike. Their lightweight, versatile nature, combined with the benefits of high precision and cost-effectiveness, makes them an attractive choice for a wide range of applications. By understanding the advantages and best practices associated with metal leaves, you can successfully incorporate them into your welding projects, creating high-quality and innovative structures that stand the test of time. Whether you're crafting art or engineering components, metal leaves can elevate your welding capabilities to new heights.

-

Why Choose TJJ as Your Window and Door Hardware Manufacturer?NewsOct.28,2024

-

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenNewsOct.28,2024

-

Aluminium Windows Profiles: Benefits and FeaturesNewsOct.28,2024

-

Innovations in Cast Iron Panel TechnologyNewsOct.28,2024

-

The Benefits of Customizing Your Wrought Iron Fence PartsNewsOct.28,2024

-

The Immortal Legacy of Cast Iron Spears: From War to Decorative UseNewsOct.21,2024

-

Why Choose TJJ as Your Window and Door Hardware Manufacturer?Oct-28-2024Why Choose TJJ as Your Window and Door Hardware Manufacturer?

Why Choose TJJ as Your Window and Door Hardware Manufacturer?Oct-28-2024Why Choose TJJ as Your Window and Door Hardware Manufacturer? -

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenOct-28-2024The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your Kitchen

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenOct-28-2024The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your Kitchen -

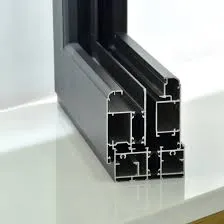

Aluminium Windows Profiles: Benefits and FeaturesOct-28-2024Aluminium Windows Profiles: Benefits and Features

Aluminium Windows Profiles: Benefits and FeaturesOct-28-2024Aluminium Windows Profiles: Benefits and Features