2 月 . 13, 2025 02:39

Back to list

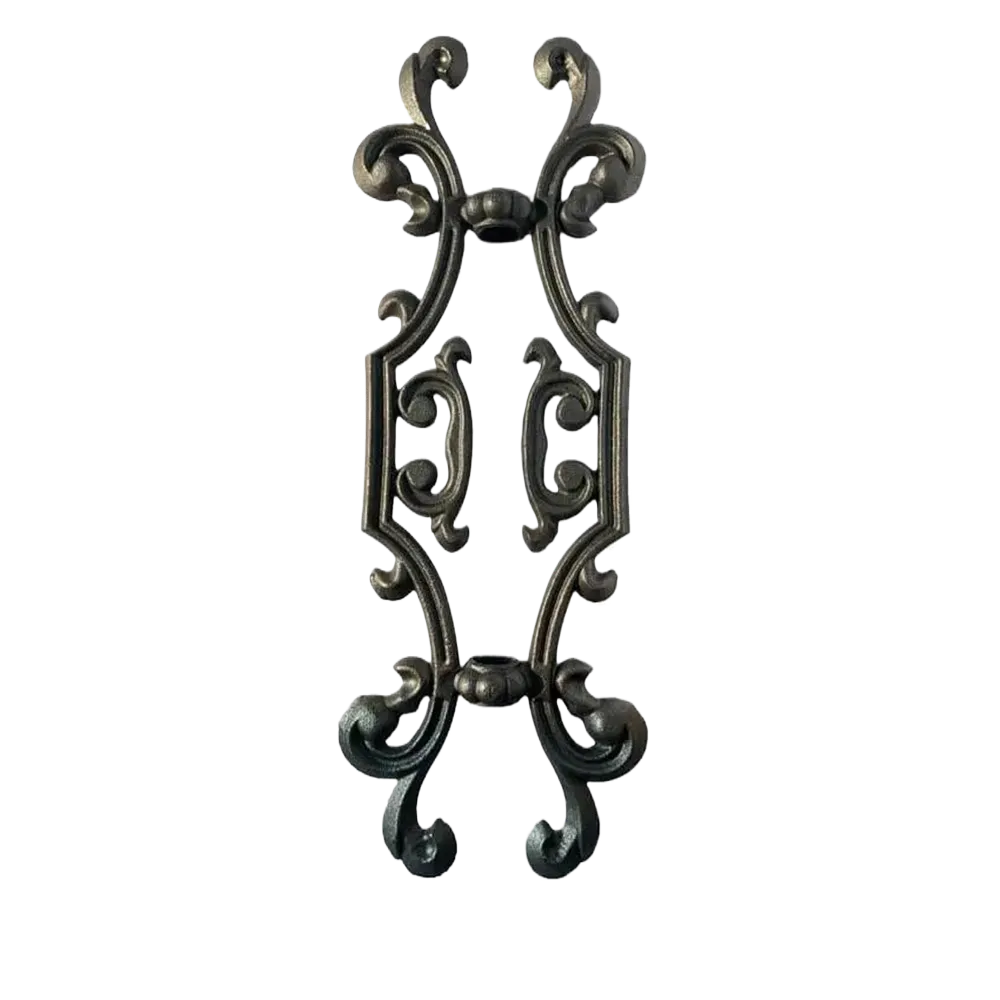

wheel for sliding door

The Evolution and Importance of Sliding Wheel Channels in Modern Engineering

The essential nature of sliding wheel channels in modern mechanical systems underscores the need for continuous innovation and improvement. Research and development initiatives focus on enhancing material properties and design features, aiming to produce channels that offer longer lifespans and improved functionality. Advances in material science, such as the development of self-lubricating polymers, reduce maintenance needs and improve the efficiency of sliding wheel channels. Furthermore, the integration of smart technology allows for predictive maintenance, where sensors and software systems can predict potential failures and provide alerts for timely maintenance, thereby minimizing downtime and repair costs. From an ecological perspective, the sustainability of sliding wheel channels is gaining attention as industries move towards greener solutions. The manufacturing process is being refined to minimize waste and energy consumption, with a focus on recycling and reusability of materials. This shift not only contributes positively to the environment but also enhances the reputation and trustworthiness of the brands leading these changes. The expertise involved in designing sliding wheel channels is evident in the precise calculations and simulations conducted during the development phase. Engineers utilize advanced CAD software to simulate real-world conditions, allowing for fine-tuning of the channels' design to achieve the best possible performance. These simulations account for variables such as load distribution, frictional forces, and thermal expansion, ensuring that the final product will perform flawlessly under anticipated conditions. Experience gained from decades of development and real-world applications underscores the importance of sliding wheel channels across diverse sectors. Companies that incorporate these components into their products often conduct field tests, gathering data on performance and durability under various environmental conditions. Feedback from these tests informs further product refinement, ensuring continuous improvement and adaptation to emerging needs. In conclusion, the role of sliding wheel channels in modern engineering is undeniably pivotal. Their evolution is a testament to human ingenuity and a commitment to improving the efficiency and reliability of mechanical systems. As technology advances, the development and refinement of these channels will continue to support progress across industries, maintaining their status as an indispensably authoritative and trusted component in engineering design and application.

The essential nature of sliding wheel channels in modern mechanical systems underscores the need for continuous innovation and improvement. Research and development initiatives focus on enhancing material properties and design features, aiming to produce channels that offer longer lifespans and improved functionality. Advances in material science, such as the development of self-lubricating polymers, reduce maintenance needs and improve the efficiency of sliding wheel channels. Furthermore, the integration of smart technology allows for predictive maintenance, where sensors and software systems can predict potential failures and provide alerts for timely maintenance, thereby minimizing downtime and repair costs. From an ecological perspective, the sustainability of sliding wheel channels is gaining attention as industries move towards greener solutions. The manufacturing process is being refined to minimize waste and energy consumption, with a focus on recycling and reusability of materials. This shift not only contributes positively to the environment but also enhances the reputation and trustworthiness of the brands leading these changes. The expertise involved in designing sliding wheel channels is evident in the precise calculations and simulations conducted during the development phase. Engineers utilize advanced CAD software to simulate real-world conditions, allowing for fine-tuning of the channels' design to achieve the best possible performance. These simulations account for variables such as load distribution, frictional forces, and thermal expansion, ensuring that the final product will perform flawlessly under anticipated conditions. Experience gained from decades of development and real-world applications underscores the importance of sliding wheel channels across diverse sectors. Companies that incorporate these components into their products often conduct field tests, gathering data on performance and durability under various environmental conditions. Feedback from these tests informs further product refinement, ensuring continuous improvement and adaptation to emerging needs. In conclusion, the role of sliding wheel channels in modern engineering is undeniably pivotal. Their evolution is a testament to human ingenuity and a commitment to improving the efficiency and reliability of mechanical systems. As technology advances, the development and refinement of these channels will continue to support progress across industries, maintaining their status as an indispensably authoritative and trusted component in engineering design and application.

Next:

Latest news

-

Why Choose TJJ as Your Window and Door Hardware Manufacturer?NewsOct.28,2024

-

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenNewsOct.28,2024

-

Aluminium Windows Profiles: Benefits and FeaturesNewsOct.28,2024

-

Innovations in Cast Iron Panel TechnologyNewsOct.28,2024

-

The Benefits of Customizing Your Wrought Iron Fence PartsNewsOct.28,2024

-

The Immortal Legacy of Cast Iron Spears: From War to Decorative UseNewsOct.21,2024

-

Why Choose TJJ as Your Window and Door Hardware Manufacturer?Oct-28-2024Why Choose TJJ as Your Window and Door Hardware Manufacturer?

Why Choose TJJ as Your Window and Door Hardware Manufacturer?Oct-28-2024Why Choose TJJ as Your Window and Door Hardware Manufacturer? -

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenOct-28-2024The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your Kitchen

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenOct-28-2024The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your Kitchen -

Aluminium Windows Profiles: Benefits and FeaturesOct-28-2024Aluminium Windows Profiles: Benefits and Features

Aluminium Windows Profiles: Benefits and FeaturesOct-28-2024Aluminium Windows Profiles: Benefits and Features