Sliding Window Roller Components for Smooth Operation and Easy Maintenance

Understanding Sliding Window Roller Parts A Comprehensive Guide

Sliding windows are a popular choice in modern architecture due to their aesthetic appeal and practicality. Whether in residential or commercial settings, these windows not only enhance the visual appeal of a structure but also offer functionality and ease of use. One of the essential components that enable smooth operation of sliding windows is the roller system. This article delves into the various parts of sliding window rollers, their functions, and why maintaining them is crucial for optimal performance.

What Are Sliding Window Rollers?

Sliding window rollers are cylindrical devices that allow the window to move smoothly along a track. They are typically located at the base of the window frame and play a pivotal role in ensuring that the window opens and closes effortlessly. The effectiveness of these rollers can significantly impact the overall functionality of the sliding window.

Components of Sliding Window Rollers

A sliding window roller system consists of several key parts

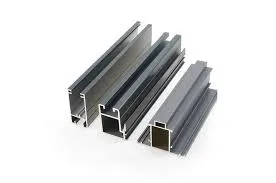

1. Rollers These are the most crucial components and are designed to fit into the tracks of the window frame. Made from materials like nylon, steel, or a combination of both, rollers come in various shapes and sizes to accommodate different window frames.

2. Housing The housing is the protective casing that holds the rollers in place. It also helps to keep the rollers aligned within the track, ensuring smooth movement.

3. Track While not part of the roller itself, the track is an integral component of the sliding window system. It is the surface on which the rollers move. Regular maintenance of the track is essential to prevent debris build-up, which can hinder the movement of the rollers.

4. Adjustment Mechanism Many sliding window rollers come with an adjustment feature, allowing for height or tension adjustments. This mechanism ensures that the window is snugly fitted against the frame, reducing air and water infiltration.

5. End Caps These components serve as a barrier at the ends of the roller track, preventing the rollers from sliding off the track. They also add stability to the overall structure of the window.

Importance of Proper Functioning Rollers

sliding window roller parts

The efficiency of sliding windows is heavily reliant on the condition of the roller system. A well-functioning roller can enhance the user experience by providing smooth and easy access to natural light and ventilation. Conversely, damaged or worn-out rollers can lead to various problems, including

- Difficulty Opening or Closing When rollers become misaligned or damaged, they can cause the window to stick, making it challenging to open or close properly.

- Increased Wear and Tear Difficulty in operation can lead to increased strain on other components of the window system, causing premature wear and potential failure.

- Water and Air Leaks Misalignment due to faulty rollers can create gaps in the window seal, leading to drafts and water leaks, which can damage the interior spaces.

Maintenance Tips

To ensure that your sliding window rollers function optimally, consider the following maintenance tips

1. Regular Cleaning Periodically clean the track and rollers to remove any debris, dirt, or residue that could impede movement.

2. Lubrication Use a silicone-based lubricant on the rollers and tracks to reduce friction and enhance smooth operation.

3. Check Alignment Regularly inspect the alignment of the rollers and adjust as necessary to ensure optimal performance.

4. Replace Worn Parts If you notice any signs of wear or damage in the rollers or housing, address these issues promptly to prevent further complications.

Conclusion

Sliding window rollers are integral to maintaining the functionality and longevity of sliding windows. By understanding their parts and ensuring regular maintenance, window owners can enjoy the benefits of easy operation and enhanced energy efficiency. Whether you are constructing a new building or maintaining an existing one, paying attention to your sliding window roller system will ensure that your windows continue to serve their purpose effectively for years to come.

-

Why Choose TJJ as Your Window and Door Hardware Manufacturer?NewsOct.28,2024

-

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenNewsOct.28,2024

-

Aluminium Windows Profiles: Benefits and FeaturesNewsOct.28,2024

-

Innovations in Cast Iron Panel TechnologyNewsOct.28,2024

-

The Benefits of Customizing Your Wrought Iron Fence PartsNewsOct.28,2024

-

The Immortal Legacy of Cast Iron Spears: From War to Decorative UseNewsOct.21,2024

-

Why Choose TJJ as Your Window and Door Hardware Manufacturer?Oct-28-2024Why Choose TJJ as Your Window and Door Hardware Manufacturer?

Why Choose TJJ as Your Window and Door Hardware Manufacturer?Oct-28-2024Why Choose TJJ as Your Window and Door Hardware Manufacturer? -

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenOct-28-2024The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your Kitchen

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenOct-28-2024The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your Kitchen -

Aluminium Windows Profiles: Benefits and FeaturesOct-28-2024Aluminium Windows Profiles: Benefits and Features

Aluminium Windows Profiles: Benefits and FeaturesOct-28-2024Aluminium Windows Profiles: Benefits and Features