2 月 . 15, 2025 04:39

Back to list

decorative cast iron

Forged iron, known in Romanian as varf forjat, holds a notable place in both industrial manufacturing and the realms of art and design. Over centuries, the art of forging iron has transformed from a practical necessity into a coveted craft, with applications stretching from durable industrial components to intricate works of art.

From an artistic perspective, varf forjat offers almost limitless possibilities. Designers and artists gravitate towards this medium for both its robustness and its aesthetic versatility. The malleability of hot iron allows artists to experiment with textures and forms, crafting anything from minimalist modern sculptures to elaborate, baroque-style gates and balustrades. These works are often found embellishing public spaces, historic buildings, and luxury homes, admired for their intricate detail and enduring nature. In terms of authoritativeness, the global recognition of blacksmithing masters over millennia positions forged iron as a topic imbued with historical significance and expert lineage. Esteemed institutions and guilds continue to uphold the traditions and standards of this ancient craft, offering certifications and apprenticeships that modernize skills while preserving the foundational techniques. Trust in forged iron products is further solidified by the reputations of well-established workshops and businesses that adhere to stringent quality controls. These entities often provide warranties and guarantees, reflecting their confidence in their products' longevity and resilience. Furthermore, customer testimonials highlight satisfaction and enduring performance as key selling points, serving as an influential factor for prospective buyers. In summary, varf forjat is not just a testament to the intersection of tradition and modernity, but also an embodiment of craftsmanship that melds Experience, Expertise, Authoritativeness, and Trustworthiness. Whether appreciated as functional hardware or celebrated as a canvas for artistic expression, forged iron continues to be a material of choice for those who value strength, beauty, and tradition. For anyone associated with the design, manufacturing, or installation of forged iron pieces, deep knowledge and appreciation of its properties and possibilities remain paramount, ensuring that this ancient craft continues to thrive in contemporary applications.

From an artistic perspective, varf forjat offers almost limitless possibilities. Designers and artists gravitate towards this medium for both its robustness and its aesthetic versatility. The malleability of hot iron allows artists to experiment with textures and forms, crafting anything from minimalist modern sculptures to elaborate, baroque-style gates and balustrades. These works are often found embellishing public spaces, historic buildings, and luxury homes, admired for their intricate detail and enduring nature. In terms of authoritativeness, the global recognition of blacksmithing masters over millennia positions forged iron as a topic imbued with historical significance and expert lineage. Esteemed institutions and guilds continue to uphold the traditions and standards of this ancient craft, offering certifications and apprenticeships that modernize skills while preserving the foundational techniques. Trust in forged iron products is further solidified by the reputations of well-established workshops and businesses that adhere to stringent quality controls. These entities often provide warranties and guarantees, reflecting their confidence in their products' longevity and resilience. Furthermore, customer testimonials highlight satisfaction and enduring performance as key selling points, serving as an influential factor for prospective buyers. In summary, varf forjat is not just a testament to the intersection of tradition and modernity, but also an embodiment of craftsmanship that melds Experience, Expertise, Authoritativeness, and Trustworthiness. Whether appreciated as functional hardware or celebrated as a canvas for artistic expression, forged iron continues to be a material of choice for those who value strength, beauty, and tradition. For anyone associated with the design, manufacturing, or installation of forged iron pieces, deep knowledge and appreciation of its properties and possibilities remain paramount, ensuring that this ancient craft continues to thrive in contemporary applications.

Next:

Latest news

-

Why Choose TJJ as Your Window and Door Hardware Manufacturer?NewsOct.28,2024

-

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenNewsOct.28,2024

-

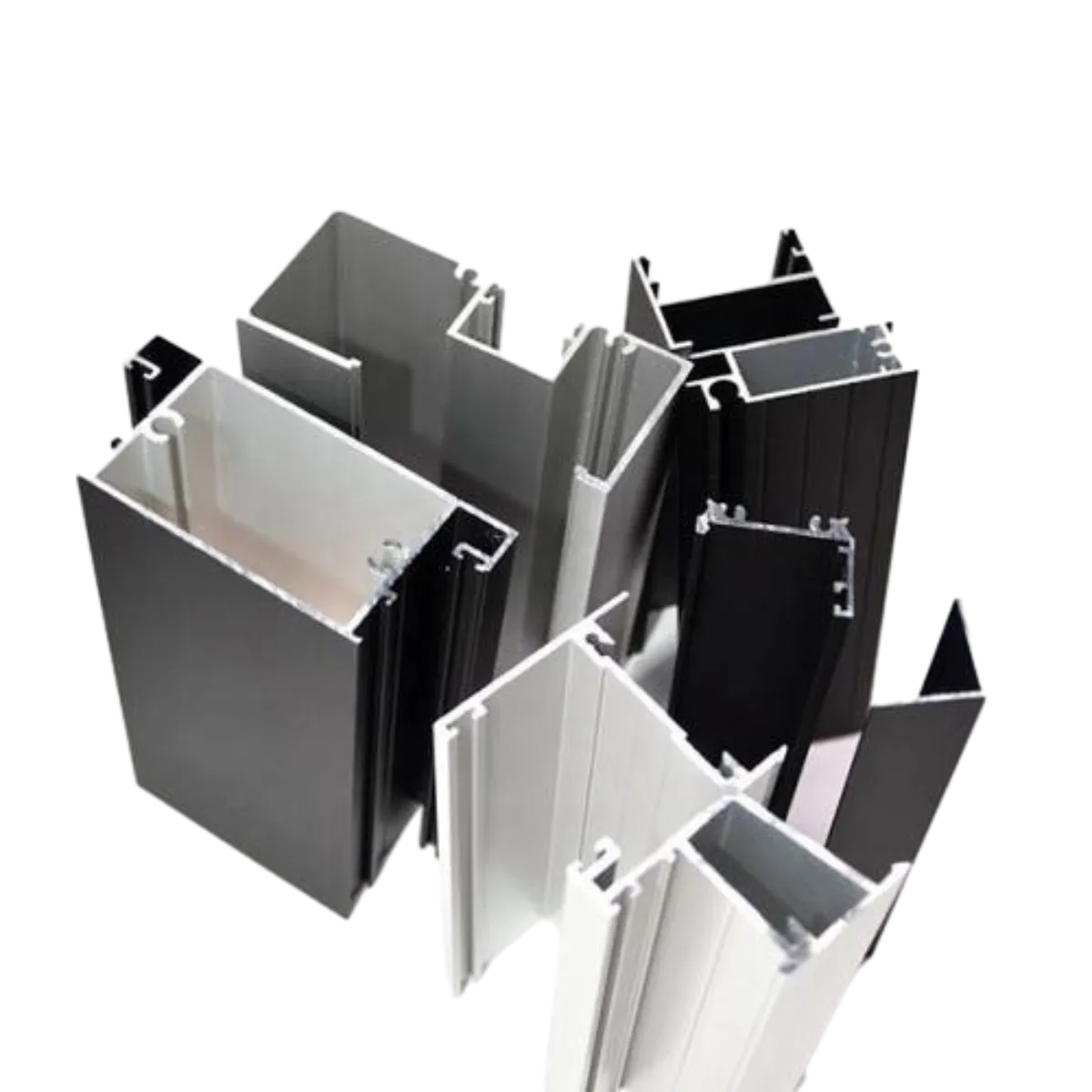

Aluminium Windows Profiles: Benefits and FeaturesNewsOct.28,2024

-

Innovations in Cast Iron Panel TechnologyNewsOct.28,2024

-

The Benefits of Customizing Your Wrought Iron Fence PartsNewsOct.28,2024

-

The Immortal Legacy of Cast Iron Spears: From War to Decorative UseNewsOct.21,2024

-

Why Choose TJJ as Your Window and Door Hardware Manufacturer?Oct-28-2024Why Choose TJJ as Your Window and Door Hardware Manufacturer?

Why Choose TJJ as Your Window and Door Hardware Manufacturer?Oct-28-2024Why Choose TJJ as Your Window and Door Hardware Manufacturer? -

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenOct-28-2024The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your Kitchen

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenOct-28-2024The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your Kitchen -

Aluminium Windows Profiles: Benefits and FeaturesOct-28-2024Aluminium Windows Profiles: Benefits and Features

Aluminium Windows Profiles: Benefits and FeaturesOct-28-2024Aluminium Windows Profiles: Benefits and Features