wrought iron manufacturers

The Evolution and Importance of Wrought Iron Manufacturers

Wrought iron has played a pivotal role in the development of various industries, architecture, and craftsmanship throughout history. Originating in ancient times, the process of manufacturing wrought iron has evolved significantly, allowing manufacturers to meet the demands of modern applications, from structural components to decorative elements. Understanding the timeline and importance of wrought iron manufacturers provides insight into a unique blend of art and engineering that continues to thrive.

Historically, wrought iron is characterized by its malleability and ductility, owing to its relatively low carbon content compared to cast iron. The production process involved heating iron ore to forge it into usable shapes, which made it lightweight yet strong, ideal for a myriad of applications. Skilled blacksmiths and metalworkers were the original wrought iron manufacturers, utilizing simple tools and techniques that required immense craftsmanship and expertise.

By the 18th century, with the onset of the Industrial Revolution, wrought iron manufacturing saw a transformation. The introduction of new technologies, such as the puddling process, allowed for more efficient production, leading to increased availability and a drop in cost. This facilitated its use in large-scale applications, notably in the construction of bridges, railways, and buildings. The iconic use of wrought iron in structures like the Eiffel Tower and various Victorian architectural pieces highlights its durability and aesthetic appeal.

Today, wrought iron manufacturers have embraced modern technology while still respecting traditional techniques. They employ advanced methods such as computer-aided design (CAD) systems to create intricate and custom designs. This blend of old and new enables manufacturers to cater to a variety of markets, from construction to home decor. The versatility of wrought iron makes it suitable for railings, gates, furniture, and more, all of which can be tailored to match specific architectural styles and personal preferences.

wrought iron manufacturers

One of the significant factors contributing to the importance of wrought iron manufacturers is sustainability. Wrought iron is recyclable, and the modern industry emphasizes eco-friendly practices. Manufacturers often use recycled materials in their production processes, significantly reducing the environmental impact compared to other materials like concrete or steel. This focus on sustainability resonates with today's consumers, who are increasingly concerned about environmental issues.

Moreover, wrought iron manufacturers contribute to local economies by creating jobs and supporting craftsmanship. Many of these manufacturers collaborate with local artisans to produce unique pieces that not only serve functional purposes but also contribute to the cultural heritage of their regions. This partnership enhances the artisanal aspect of wrought iron production, providing opportunities for skills transfer and preservation of traditional techniques.

In addition to their economic contributions, wrought iron manufacturers also play a role in fostering innovation within the industry. With advancements in metallurgy, there have been new alloys and treatments developed that enhance the strength and corrosion resistance of wrought iron. Manufacturers are continuously researching and testing new methods to improve their products, ensuring they remain competitive in an ever-evolving market.

Challenges do exist for wrought iron manufacturers, particularly given the increasing competition from alternative materials such as aluminum and stainless steel. These materials often present lower costs and lighter weights, appealing to the modern construction market. However, the uniqueness and craftsmanship associated with wrought iron remain irreplaceable. Manufacturers are encouraged to highlight these distinct attributes and educate consumers on the long-term benefits of investing in wrought iron products.

In conclusion, wrought iron manufacturers hold an esteemed place in the history of metalworking and manufacturing. Their ability to blend traditional craftsmanship with modern technology enables them to produce a wide range of products that serve practical and aesthetic purposes. As they adapt to focus on sustainability and innovation, these manufacturers are not only preserving a vital aspect of our industrial heritage but are also paving the way for its future in an increasingly environmentally conscious world. The legacy of wrought iron will undoubtedly continue, fueled by the dedication and ingenuity of its manufacturers.

-

Why Choose TJJ as Your Window and Door Hardware Manufacturer?NewsOct.28,2024

-

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenNewsOct.28,2024

-

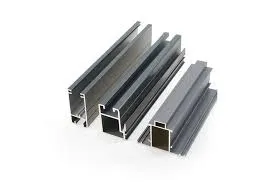

Aluminium Windows Profiles: Benefits and FeaturesNewsOct.28,2024

-

Innovations in Cast Iron Panel TechnologyNewsOct.28,2024

-

The Benefits of Customizing Your Wrought Iron Fence PartsNewsOct.28,2024

-

The Immortal Legacy of Cast Iron Spears: From War to Decorative UseNewsOct.21,2024

-

Why Choose TJJ as Your Window and Door Hardware Manufacturer?Oct-28-2024Why Choose TJJ as Your Window and Door Hardware Manufacturer?

Why Choose TJJ as Your Window and Door Hardware Manufacturer?Oct-28-2024Why Choose TJJ as Your Window and Door Hardware Manufacturer? -

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenOct-28-2024The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your Kitchen

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenOct-28-2024The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your Kitchen -

Aluminium Windows Profiles: Benefits and FeaturesOct-28-2024Aluminium Windows Profiles: Benefits and Features

Aluminium Windows Profiles: Benefits and FeaturesOct-28-2024Aluminium Windows Profiles: Benefits and Features