wrought iron rust

The Enduring Legacy of Wrought Iron and the Challenge of Rust

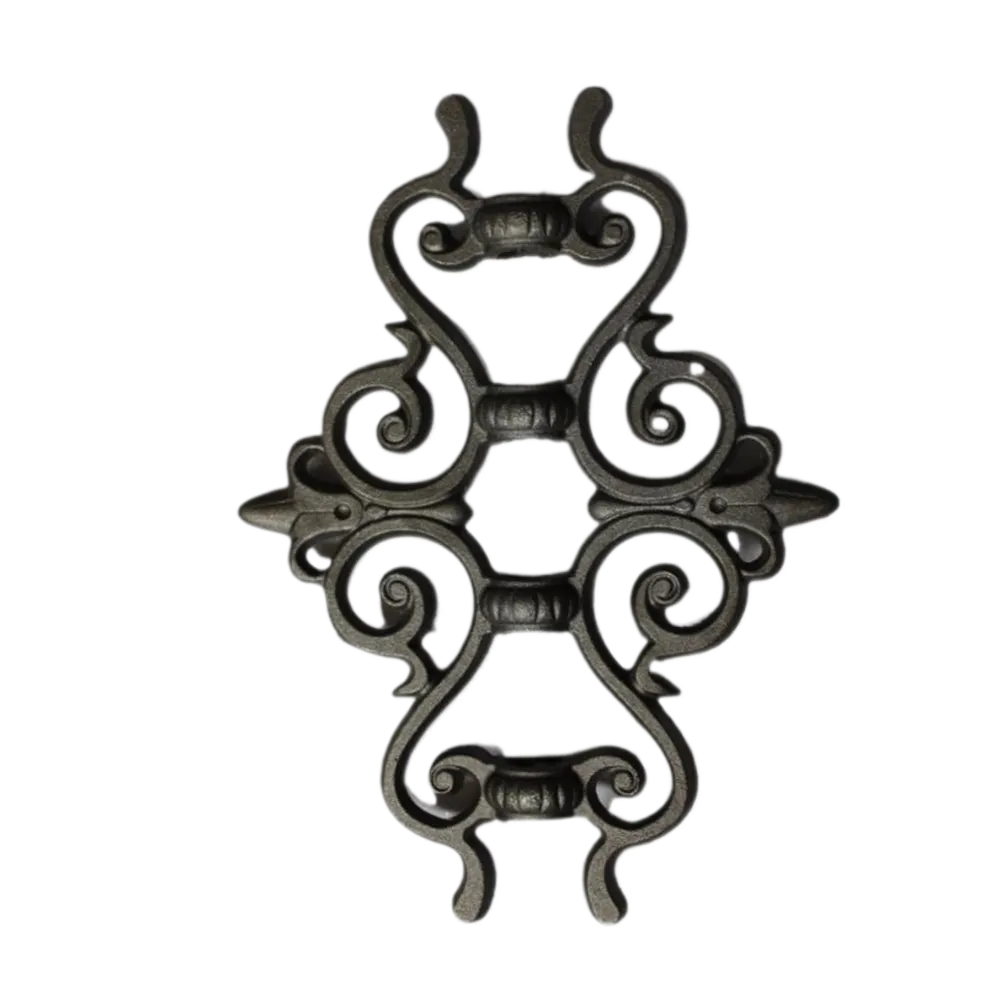

Wrought iron, a form of iron that is processed to create a malleable and ductile material, has played a crucial role in architecture, construction, and artistry throughout history. Its unique properties make it a preferred choice for a variety of applications, from railings and gates to intricate ornamental designs. However, the beauty and utility of wrought iron come with a significant drawback rust.

Rust, the oxidation of iron, occurs when iron or its alloys react with oxygen and moisture in the environment. This chemical process, known as corrosion, poses a considerable threat to wrought iron structures. Over time, rust not only degrades the material's physical properties but can also compromise its aesthetic appeal. Therefore, understanding wrought iron rust and its prevention is essential for both preservation and functionality of wrought iron structures.

Historically, wrought iron has been cherished for its strength, flexibility, and resistance to impact. Its production dates back to the Iron Age, where it was shaped through hand tools and heat. This manual method of creation allowed artisans to produce pieces that were not only robust but also artistically adorned. The resulting objects, from railings to architectural elements, were often celebrated for their beauty and craftsmanship.

The Enduring Legacy of Wrought Iron and the Challenge of Rust

To combat the effects of rust on wrought iron, a variety of protective methods are employed. One of the most common techniques is painting. Applying a coat of paint not only adds color but also forms a barrier between the metal and the elements. Specialized paints designed for metal surfaces can significantly prolong the life of wrought iron by preventing moisture from making contact with the iron.

wrought iron rust

Another effective method of protection is galvanization, a process where iron is coated with a layer of zinc. This zinc layer serves as a sacrificial anode, corroding in place of the iron beneath it. While galvanization is more common in modern applications, it has become a popular choice in preserving wrought iron structures, especially those exposed to harsh weather conditions.

Regular maintenance is also crucial in preventing rust. Inspecting wrought iron for signs of wear, such as flaking paint or visible rust spots, can help identify issues before they become severe. Promptly addressing these concerns—whether through repainting or treating rusted areas—can extend the life of wrought iron significantly.

In addition to maintenance, the environmental conditions surrounding wrought iron installations play a significant role in the development of rust. Areas with high humidity, salt exposure near coastal regions, or significant temperature fluctuations can accelerate the rate of corrosion. For these reasons, selecting the appropriate location for wrought iron installations and considering local climate conditions can be strategic in avoiding rust issues.

While wrought iron demonstrates resilience and strength, its susceptibility to rust serves as a reminder of the delicate balance between beauty and deterioration. Each piece bears witness to the passage of time, and without proper care and attention, the legacy of wrought iron can be marred by the very substance that gives it character—rust.

In conclusion, the history and craftsmanship of wrought iron are profoundly valuable, but they come with the responsibility of preservation. Understanding the nature of rust and implementing effective protective measures ensures that the elegance and functionality of wrought iron can be enjoyed by future generations. As custodians of these historic works, we must remain vigilant in our efforts to maintain this remarkable material, safeguarding it against the inevitable march of time.

-

Why Choose TJJ as Your Window and Door Hardware Manufacturer?NewsOct.28,2024

-

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenNewsOct.28,2024

-

Aluminium Windows Profiles: Benefits and FeaturesNewsOct.28,2024

-

Innovations in Cast Iron Panel TechnologyNewsOct.28,2024

-

The Benefits of Customizing Your Wrought Iron Fence PartsNewsOct.28,2024

-

The Immortal Legacy of Cast Iron Spears: From War to Decorative UseNewsOct.21,2024

-

Why Choose TJJ as Your Window and Door Hardware Manufacturer?Oct-28-2024Why Choose TJJ as Your Window and Door Hardware Manufacturer?

Why Choose TJJ as Your Window and Door Hardware Manufacturer?Oct-28-2024Why Choose TJJ as Your Window and Door Hardware Manufacturer? -

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenOct-28-2024The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your Kitchen

The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your KitchenOct-28-2024The Advantages of Cast Iron Stove Plates: A Timeless Choice for Your Kitchen -

Aluminium Windows Profiles: Benefits and FeaturesOct-28-2024Aluminium Windows Profiles: Benefits and Features

Aluminium Windows Profiles: Benefits and FeaturesOct-28-2024Aluminium Windows Profiles: Benefits and Features